In my previous posting Current sensor for multi core cable is talked about measuring AC current flowing on cable where you don’t get access to individual wires. In that posting I mentioned that I saw Modern Device blog article Current Sensor that seem to be doing exactly that. This sensor is designed for providing an isolated current sensor for mains voltages wires. It uses a pair of Hall Effect Sensors to sense the magnetic field generated by current in a wire. The sensor output is just an analog voltage which is proportional to the current sensed on the cable.

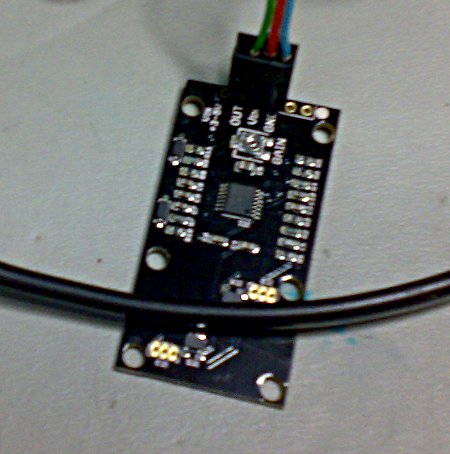

Some days ago I got the sensor and started some testing with it. Here is a picture of the unit test on lab table:

This sensor is designed to run at either 3.3 or 5 volts, and accept all voltages on that range. I set my lab power supply to 4.9 volts on my tests. The sensor seems to take around 16 mA current from the power supply.

The output is claimed to be fairly linear DC voltage proportional to AC current on cable. The circuit outputs DC voltage proportional to the current on the cable. The voltage is almost zero (some tens of millivolts) when there is no current flowing between the sensors. Based on my tests with few different currents the output seems to to be OK in linearity. The device designer is from USA (110V 60Hz power), but the circuit is designed in such way that it works also well in Europe where mains power is 230V 50Hz.

The downside of this sensor design is that the way the cable is put between the hall sensors has lots of effect on the output. This was somewhat expected.

I did some tests with a “flat” shape mains cable and got quite different results depending on the way the cable is put on the sensor. If you put the flat cable “flat” on circuit board between the sensors, the output is zero or almost zero. Changing the cable to stand on the circuit board so that one wire is between sensors and other higher up gives highest reading, with the sensor default calibration I got around 1 mV / mA readings.

When the cable is between those different extremes, the output varies between those maximum and minimum. What happens here gives also ideas how this sensor works. It looks like the description at Current Sensor article might not be completely accurate:

Two linear hall effect sensors, in surface mount packages are mounted in close proximity to the conductors. They are oriented so that each sensor is closer to one of the wires in the cable. The AC voltage from the sensors is then subtracted, so that common mode noise will drop out, and filtered with a low-pass filter to eliminate any signals greater than the power line frequency.

It seems because I get the highest reading when one of the mains cable conductors was between the sensors (about same distance to both sensors), and the the other is higher up on top of that (longer distance from sensors, but approx same distance to both sensors). To me it seems that those two hall sensors sense the magnetic field from that nearest wire between the sensors well (difference gives it’s magnetic field well while attenuating well outside fields that get approximately same to both sensors). The other mains wire (carrying the return current) farther away has some effect (reduces the output) on the measurements, but due longer distance and different field direction it’s affect if very much reduced. So it is possible with calibration to cancer out it’s effect from output. If you put the cable on place where both current carrying conductors are between hall sensors, both of them get the same direction magnetic field, and it cancels out on signal processing circuit. That’s my analysis how the sensor seems to work (so I think the original description was not accurate).

I did also some test with 3 core “round” shape grounded mains power cable. The similar variations on different cable rotation directions were are also present here. I also tested with single wire going between the sensors, and I got some current readings with it.

According the lab tests it seem that the correct procedure for real life use for this device would be something like this: First put cable + sensor combination to direction where you get some useful readings (highest, almost highest, around middle or something you like). Then securely attack cable so that it does not turn. Then calibrate sensor with known load so you know what voltage matches what current. There is gain potentiometer for calibration on sensor. So I am wondering if this attaching method shown at Current Sensor blog article would give accurate results on the long run (prevent cable and sensor from turning).

In some ways this sensor is an excellent idea for measuring individual circuits in a house. Basically the sensor does what it is promised to do. The need to very securely attach it to cable and need to calibrate it for sensible readings limits it’s uses. You just can’t put it on cable (like clamp sensors on single wires) and expect to get sensible results. So this sensor is more for fixed instrumentation than “multimeter” style applications.

If you need this type of sensor, get Current Sensor from Modern Device Shop. If the limitations are too much, then look for something else.

7 Comments

T says:

Thanks for the review!

Tomi Engdahl says:

IMC-Hall Current Sensor

http://www.eeweb.com/company-news/melexis/imc-hall-current-sensor/

The new IMC-Hall current sensor MLX91205 is a single axis integrated magnetic sensor based on the Hall Effect. It produces an analog linear, ratio-metric output voltage proportional to the applied magnetic field parallel with the chip surface.

The circuit is fabricated using a standard CMOS process. The additional ferromagnetic layer (IMC-Hall = Integrated Magnetic Concentrator, Triaxis Technology) that is added in a simple post-processing step, amplifies the magnetic field and concentrates it on the Hall elements. Therefore, the circuit features very high magnetic sensitivity, low offset, and low noise.

Leland says:

It’s very simple to find out any topic on net as compared to books,

as I found this post at this web site.

Earlene says:

Your style is very unique compared to other folks I’ve read stuff

from. Thanks for posting when you have the opportunity, Guess I’ll

just book mark this web site.

Tomi Engdahl says:

MIT researchers develop a low-cost device to monitor home power consumption

https://techcrunch.com/2016/08/01/home-power/?ncid=rss&cps=gravity_1462_8043715913418486213

A team of researchers at MIT has developed a device designed to give home owners a better picture of how much power their individual appliances are eating up. The gadget, which was outlined in a paper published in a recent edition of the IEEE Sensors Journal, offers a simple installation process that involves securing it over a power line with a zip tie.

The stamp-size sensor self-calibrates and is capable of monitoring individual appliances courtesy of software developed by the team, even going so far as isolating time segments, like when a refrigerator goes into defrost mode. It also relies only minimally on cloud-based servers,

MIT estimates a commercial cost of between $25 and $30 for the sensor

What’s wasting power at home? Ask your app!

New system from MIT can identify how much power is being used by each device in a household.

http://news.mit.edu/2016/wasting-power-home-app-0801

If you want to save on your monthly electric bill and reduce your greenhouse gas emissions at the same time, you might buy a new, energy-efficient refrigerator. Or water heater. Or clothes dryer. But if you can only replace one of these, which will give you the biggest payback?

While many groups have worked on developing devices to monitor electricity use, the new MIT system has some key advantages over other approaches. First, it involves no complex installation: No wires need to be disconnected, and the placement of the postage-stamp-sized sensors over the incoming power line does not require any particular precision — the system is designed to be self-calibrating. Second, because it samples data very quickly, the sensors can pick up enough detailed information about spikes and patterns in the voltage and current that the system can, thanks to dedicated software, tell the difference between every different kind of light, motor, and other device in the home and show exactly which ones go on and off, at what times.

Own your own data

Perhaps most significantly, the system is designed so that all of the detailed information stays right inside the user’s own home, eliminating concerns about privacy that potential users may have when considering power-monitoring systems. The detailed analysis, including the potential for specialized analysis based on an individual user’s specific needs or interests, can be provided by customized apps that can be developed using the MIT team’s system.

Tests of the system have showed its potential to save energy and greenhouse emissions — and even to improve safety.

“For a long time, the premise has been that if we could get access to better information [about energy use], we would be able to create some significant savings,” Leeb says.

First was the ability to monitor changes in voltage and current without cutting the main incoming power line to a home or business (an expensive process requiring a licensed electrician) or plugging every appliance into a special monitoring device. Other groups have attempted to use wireless sensors to pick up the very faint magnetic and electric fields near a wire, but such systems have required a complex alignment process since the fields in some places can cancel each other out. The MIT team solved the problem by using an array of five sensors, each slightly offset from the others, and a calibration system that tracks the readings from each sensor and figures out which one is positioned to give the strongest signal.

every motor or device has distinctive characteristics as to exactly how fast and how much the voltage varies, or spikes, at the moment the device switches on, or as it operates.

Once the system is developed into a commercial product, Leeb says, it should cost only about $25 to $30 per home.

We’re trying to lower the barriers to installation,”

Tomi Engdahl says:

LAUNDRY MONITOR WON’T GENERATE STATIC WITH ROOMMATES

https://hackaday.com/2020/05/15/laundry-monitor-wont-generate-static-with-roommates/

[Adam] shares his wash-bots with roommates, and they aren’t close enough to combine their lights and darks and turn it into a group activity. They needed an easy way to tell when the machines are done running, and whose stuff is even in there in the first place, so [Adam] built a laundry machine monitor that uses current sensing to detect when the machines are done running and sends a text to the appropriate person.

Each machine has a little Hall effect-sensing module that’s carefully zip-tied around its power cable. The signal from these three-wire boards goes high when the machine is running and low when it’s not. At the beginning of the load, the launderer simply presses their assigned button on the control box, and the ESP32 inside takes care of the rest.

https://hackaday.io/project/169990-easy-laundry-monitor

Tomi Engdahl says:

Inductive current measuring using Raspberry Pi

https://www.youtube.com/watch?v=P47pjVyPP3w

Making a coil to inductively sense current flowing through 2-conductor house wiring cables, without modifying the house wiring.

Making a coil to inductively sense current flowing through 2-conductor house wiring cables, without modifying the house wiring.

I used a Raspberry Pi and an ADS1115 A/D converter to sense the output from my coil and graphed it using ascii graphics on the Raspberry Pi computer. I also experimented with how much current it takes to instantly pop a breaker.