I have been interested in 3D printing related technology – I have followed the development on the field and written on it. There has been many interesting open source ED printers starting from RepRap to all kinds of 3D printer designs. It is interesting to see what makes those cheap FDM devices to run.

But how more advanced 3D printers work? If you’ve ever been interested in what goes on inside a (roughly) $6000 DLP stereolithography printer, you might want to check out the recent announcement from Autodesk that open sources their electronics and firmware for their Ember 3D printer. The Ember 3D Printer from Autodesk is a DLP SLA 3D printer, so its completely different than FDM 3D printing. Here’s a basic look at how it works.

The mechanical design has been open since May

Ember’s Electronics and Firmware are now Open Source meaning that they are available for you to download, inspect, modify, and make improvements. The electronics are shared under a Creative Commons Attribution-ShareAlike license.

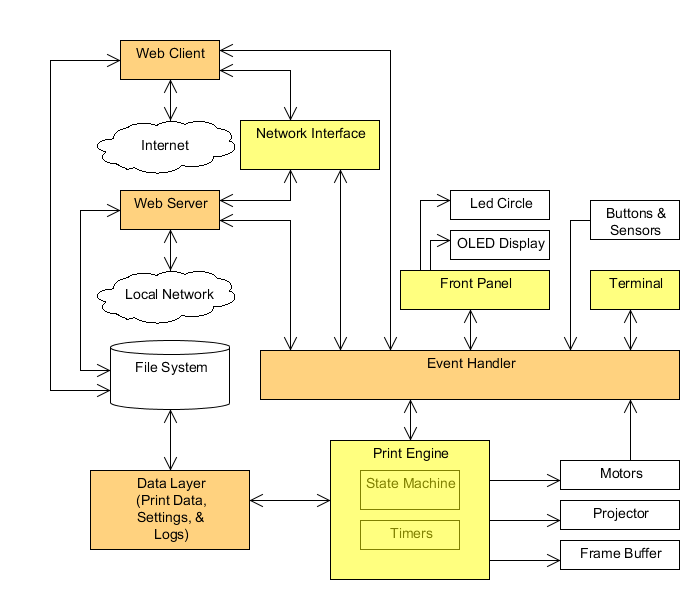

The main board integrates a clone of the BeagleBone Black and an AVR-based motor controller (6-layer board). Ember runs custom firmware in the main (Sitara) processor as well as in the AVR controllers for the front panel displays and the motors that drive the build head and resin tray. The architecture of the Sitara firmware is shown below.

Autodesk says, “Our thought is not that you would duplicate Ember, but extend it.”

To operate the printer, in addition to hardware and software, you will also need to resin from which the prints are made of. You can buy that or make it yourself as Autodesk has made resin formulation open source, as well.

0 Comments

Be the first to post a comment.