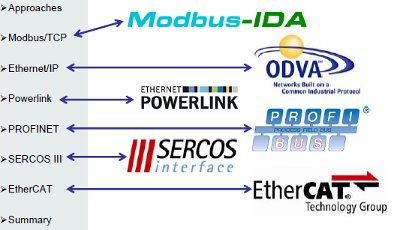

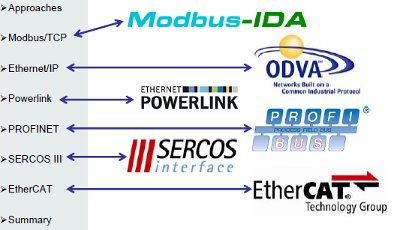

Industrial Ethernet Technologies: Overview is a presentation intended to give an overview over the most important Industrial Ethernet technologies. It is good reading for anyone working with Ethernet and/or automation applications.

Industrial Ethernet Technologies: Overview is a presentation intended to give an overview over the most important Industrial Ethernet technologies. It is good reading for anyone working with Ethernet and/or automation applications.

4 Comments

Mackeran says:

Are you a professional journalist? You write very well.

Tomi Engdahl says:

Industrial Ethernet—The basics

http://www.eetimes.com/design/industrial-control/4391544/Industrial-Ethernet-The-basics?Ecosystem=communications-design

When you talk about office and home networking, typically you’re talking about Ethernet-based networks—computers, printers and other devices that contain Ethernet interfaces connected together via Ethernet hubs, switches and routers. In the industrial area the networking picture is more complex. Now, Ethernet is becoming a bigger part of that picture. This article is an introduction to the basics of Ethernet, with a bit of added detail on how it fits into the industrial networking picture.

Tomi Engdahl says:

A history of industrial Ethernet protocols and their benefits

https://e2e.ti.com/blogs_/b/industrial_strength/posts/a-history-of-industrial-ethernet-protocols-and-their-benefits?HQS=sys-ind-fa-robotics21-agg-ta-ElectronicDesign-wwe&DCM=yes&dclid=COWa7Yj-5PMCFRymGAodIIwBHg

Every industrial Ethernet protocol has a unique history and differing benefits for industrial applications. In this article, I’ll provide a brief overview and key benefits for three key protocols: EtherCAT, Profinet and multiprotocols.

Industrial Ethernet is used for factory automation, building automation and many other industrial applications. A key benefit of industrial Ethernet over standard Ethernet is the deterministic real-time data exchange and isochronous cycle time – less than 1 ms.

You cannot implement most industrial Ethernet standards with standard Ethernet media access control (MAC); instead, you’ll need a dedicated application-specific integrated circuit (ASIC) or field-programmable gate array (FPGA). That is because the Ethernet frame is received as “cut-through,” which means that while the first Ethernet port is receiving the frame, a dedicated industrial Ethernet MAC hardware block is already processing and transmitting that frame onto the second Ethernet port. The cut-through method can achieve a port-to-port delay of less than 1 µs for an Ethernet frame.

EtherCAT

An invention of Beckhoff Automation, Ethernet for control automation technology (EtherCAT) has lived under the EtherCAT Technology Group umbrella since 2003. On the technical side, EtherCAT is a controller-and-device network architecture, as shown in Figure 1. The EtherCAT device has two Ethernet connectors in order to support a simple line topology. An EtherCAT network can support as many as 65,535 EtherCAT devices.

Only the EtherCAT controller generates an EtherCAT frame; all devices receive and process this frame. The last device loops back the EtherCAT frame, and the EtherCAT frame travels back through all devices (without further processing) to the controller. The EtherCAT frame has reserved space to process data for each device, and none of the devices change the frame length itself.

An EtherCAT device requires specific Ethernet hardware (EtherCAT MAC) support, as it needs to process incoming EtherCAT frames as they arrive. Typical implementations use ASICs or FPGAs

Profinet

Process field network (Profinet) is one of the leading industrial Ethernet standards for factory automation. There are different versions of Profinet, but in this article, I’ll focus on Profinet input/output (I/O).

Profinet operates on full-duplex 100-Mbps Ethernet and has a device-and-controller network architecture

It consists of a Profinet controller that takes over the controller role in the network; I/O devices take over the device roles. Profinet is very flexible in terms of network topology and includes line topology, ring topology, star topology or combinations of these topologies using hub and switch devices.

Over the years, the Profinet standard has evolved based on market requirements. Various kinds of performance classes are simply named A, B and C. Each performance class adds more functions than the class below, an approach that enables Profinet to be backward-compatible with previous Profinet device generations.

Multiprotocol

Because of the number of industrial protocols offered, product manufacturers have not defined a common industrial Ethernet standard; instead, the field is fragmented. Many leading manufacturers have defined a specific industrial Ethernet standard to fit their needs, often derived from one of their existing serial-based field buses.

Adding an industrial Ethernet standard to a product and then certifying the communication interface with certification bodies has its challenges. Most manufacturers need to support multiple industrial Ethernet protocols in order to sell their equipment to customers using different standards. One way to add multiple Ethernet standards to a product is to create separate printed circuit board (PCB) modules for each industrial Ethernet standard. You plug one of the modules into the main board at a time. Exchanging the protocol always requires a hardware change, however, which makes the product more complex in terms of the bill of materials (BOM) and the need to produce multiple PCB modules and source multichip solutions.

To solve this challenge, designers can use products such as the Sitara™ Arm® processor. These application processors have an integrated PRU-ICSS, which is able to operate multiprotocol industrial Ethernet. Let’s review the key differences and advantages of this solution. Learn more about multiprotocol support in our demo video and get the software.

The PRU loads industrial Ethernet protocol firmware at device run time. There are PRU-ICSS protocol firmware releases available for EtherCAT, Profinet, , Ethernet/IP, High-Availability Seamless Redundancy-Parallel Redundancy Protocol (HSR-PRP) or Sitara processors also support Control and Communication Link Using Industrial Ethernet (CC-Link IE) Field basic in the Processor SDK, and does not require any FPGA or ASIC.

Tomi Engdahl says:

M12 CONNECTOR CODING FOR

AUTOMATION AND INDUSTRY

4.0 COMPLIANCE

https://www.altechcorp.com/RFY/Altech-Sensor-Cables-ShortForm_WP.pdf

Connectors are critical in the ongoing operation of any kind of electronic or electrical apparatus. They are

found on every application imaginable and used to interconnect every type of sensor, control, and factory

management system out there. Overall, the M12 family of circular connectors have an important place in

this market.

Because M12 connectors are found at multiple levels in automation, several styles of coding exist to prevent incorrect

mating on products. Some considerations to keep in mind include the use of shielded connectors as well as IP

rated connectors for washdown and/or corrosive environments. IP rating includes everything from IP65, which are

dust-tight and water resistant to IP 68, which is not only dust-tight but protected against complete and continuous

submersion in water.

Sponsored byM12 Connector Coding for Automation and Industry 4.0 Compliance | 2

The five most common types of M12 connector codings include:

• A-coded connectors

As the most common style of connector, they are incorporated for use with sensors, actuators, motors, and many

other standard devices used in a wide variety of applications at the device level for DC power and signal transfer.

The connectors can vary in pin numbers from two pins to 12 pins. You’ll see these connectors used regularly in

robotics and other factory floor equipment where extreme temperatures and/or harsh operating environments

are typical.

• B-coded connectors

Most often used as network interconnects, such as Fieldbus, B-coded connectors typically have three to five pins.

These connectors are a vital component needed in IIoT and Industry 4.0 applications.

• C-coded connectors

Less common than A- or B-coded connectors, they are primarily used with AC powered devices including sensors

and actuators. The connectors also have a dual keyway for increased security. They typically have three or six pins.

• D-coded connectors

Used as network cables for Ethernet and ProfiNet protocols—which includes industrial protocols like Ethernet/IP

and EtherCat), D-coded connectors are able to transfer real time data up to 100 Mb. They typically have three to

five pins.

• X-coded connectors

These connectors are growing in popularity because of their ability to transfer large amounts of data at high speeds

through an Ethernet connection. X-coded connectors transfer up to 10 Gb of data and are ideal for high-speed

data transfer in industrial applications. While other connectors typically vary in how many pins they have, X-coded

connectors will always have eight pins. These connectors are often used in vision and industrial robotic applications

where precise data transfer is a must

Of the above five codes, the

X-coded connector is a clear indication of where the industry is

headed—into the high-speed data transfer realm—and will slowly

begin to replace some of the other connector codes as time goes

forward.