Mastech MS8209 is real multimeter that can measure almost anything. I have written some comments on Mastech MS8209 years ago.

Some technical data on the back of the multimeter.

The things I liked:

- practically all the necessary multimeter measurements including frequency and capacitance measurements

- good mechanical consruction, convient size and durable

- the test leads that came with the meter are good quality

- supports relative measurements

- has data hold

- has backlight on display

- auto power-off

- autoranging

- beeper is nice when testing wires

- frequency and dutu cycle measurements

- sound level and light level measurements are sometimes useful

- the meter came with a carrying case than can hold the meter and wires

I had two if them, liked them, used a lot for 10 years and finally they broke down. Maybe more than 10 years of quite heavy use is OK life for reasonably priced multimeter.

Now it is time to take a look at what is inside and maybe extend the life of those meters. DISASSEMBLY: Remove the two Philips-head screws from the bottom of the case and carefully lift the back off, bottom (screw holes) first.

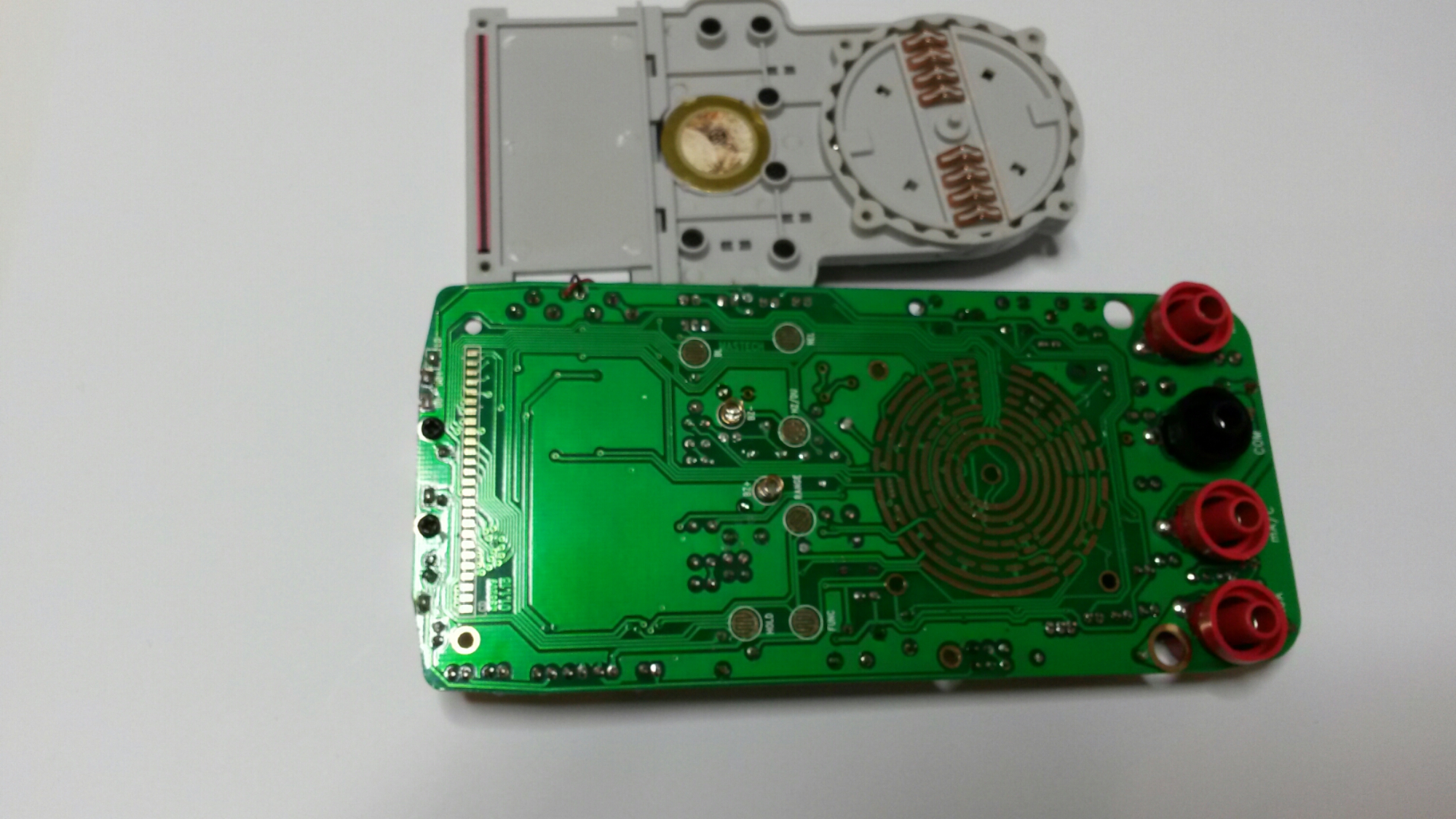

There is quite lot of components inside because there are so many measurement functions:

The weak spot is the mode switch. The metal contacts on the circuit board start to show aging. In this case the problem was that metal contact pads that are very near each other start deform on the sides/edges and make short circuits. This problem was seen on both of the multimeters that had problems. It rendered resistance measurements not to work on one multimeter and killed the electronics on other one. I got one with broken resistance range fixed by cleaning the contacts with contact spray and cleaning what is between them mechanically with a needle.

4 Comments

Tomi Engdahl says:

Dead meters expose battery terminal design issues

http://www.edn.com/electronics-blogs/powersource/4458696/Dead-meters-expose-battery-terminal-design-issues

Ever since my consultant days, I have believed that you should not scrimp when it comes to test equipment. Accordingly, when it came time to buy a DVM (digital voltmeter) I spent over $400 on a top-end Fluke meter. I really liked that it measures ac signals with true RMS. The Fluke 187 also has a capacitance meter, and could measure current from microamperes to amperes. I also believe in redundancy, so after a few years I bought a Fluke 189 true RMS meter to keep in the garage for those automotive troubleshooting episodes we all have.

I spent about the same, over $400, for the newer Fluke. These days a Fluke 189 costs $495 new, and a Fluke 187 costs between $465 and $199 refurbished. So I figured I have about $1000 in voltmeters. You can imagine my fury when both meters were dead, even with new batteries

I opened the battery compartments (Figure 2). While the present batteries in the meters had not leaked, previous leakage had caused severe corrosion on the battery terminals in the case.

When I later took the meter apart, I also saw corrosion on the dc bus bar that carries the power (Figure 5). There is no denying the injection molded case is beautiful, with all the features needed to retain the bus bars. It’s a shame the electrical engineers did not specify better plating for the battery terminals.

I was simply mad at the crappy battery terminals. The fury came when the meter still didn’t work, and I got out the second Fluke meter from the garage, and it was dead too. I cleaned its terminals with the wire brush and put in new batteries to no avail. Now I had two dead meters. Two dead meters that cost me about $1000. I figured that one of the terminals must have some non-conductive oxidation

The Klein Tools MM600 induced new waves of fury. There is absolutely no indication on the case how to put in the batteries.

Fearing that the meters would only corrode again, I got out my spray cans of DeoxIT D5 and DeoxIT G5 (Figure 11). The G5 is meant for gold-plated terminals and was in stock at the local Radio Shack. The D5 I bought on Amazon. DeoxIT works great to clean, renew, protect, and lubricate any contact surface. I learned about it from my Ham radio buddies, who have used it for decades to keep their gear working. It is also great on those rotary switches in test equipment. Lubricating connectors does not impair their conductivity, but will eliminate scuffing and spalling under vibration.

Home> Community > Blogs > PowerSource

Dead meters expose battery terminal design issues

Paul Rako -August 03, 2017

Save Follow

PRINT

PDF

EMAIL

So once I had the Klein Tools MM600 DVM working, I could see that the terminals in both Fluke meters were getting the full battery dc voltage. My fury dissolved into sorrow as I worried that I had a $1000 of dead voltmeters. I opened the Fluke meters up and they both use a set of prongs pressing against gold-plated pads to apply the battery voltage to the motherboard (Figure 10). Gently bending the prongs up to apply pressure to the pads on the circuit board fixed both meters.

Fearing that the meters would only corrode again, I got out my spray cans of DeoxIT D5 and DeoxIT G5 (Figure 11). The G5 is meant for gold-plated terminals and was in stock at the local Radio Shack. The D5 I bought on Amazon. DeoxIT works great to clean, renew, protect, and lubricate any contact surface. I learned about it from my Ham radio buddies, who have used it for decades to keep their gear working. It is also great on those rotary switches in test equipment. Lubricating connectors does not impair their conductivity, but will eliminate scuffing and spalling under vibration.

I didn’t spray the DeoxIT G5 into the meter. I just sprayed it into space, and then touched the spray tube to the gold pads in the Fluke meters

It’s nice that Fluke goes to so much trouble to make the case water resistant. I guess that is a necessity for industrial meters, but I just use mine at the lab bench or in my garage. I would rather have the batteries exposed so they leak out of the case, rather than a hermetic design that ensures the whole guts get corroded when the batteries inevitably leak. Inevitably.

Making a bad design efficiently is not an optimal business practice.

Jurgen says:

My 8209 had the same problem. Many thanks Tomi.

Tomi Engdahl says:

Digitaalinen yleismittari, 6-in-1

https://www.biltema.fi/tyokalut/mittavalineet/mittalaitteet/yleismittarit/digitaalinen-yleismittari-6-in-1-2000024214

Amir says:

Hi

Nomber of Crystal for mastech ms8209