The powerCON is an electrical connector manufactured by Neutrik for connecting mains power to equipment in a small space (smaller than IEC connector commonly used on PCs).

Neutrik powerCON 20 A is a locking 3 conductor equipment AC connector with contacts for line, neutral and pre-mating ground contact. It is a rugged solution that has a locking device in it. It is suitable for applications where a reliable power connection is needed (no loose wire accidentally pulled out of device). Neutrik powerCON 20 A is most commonly used for entertainment system power distribution (for example lighting equipment)

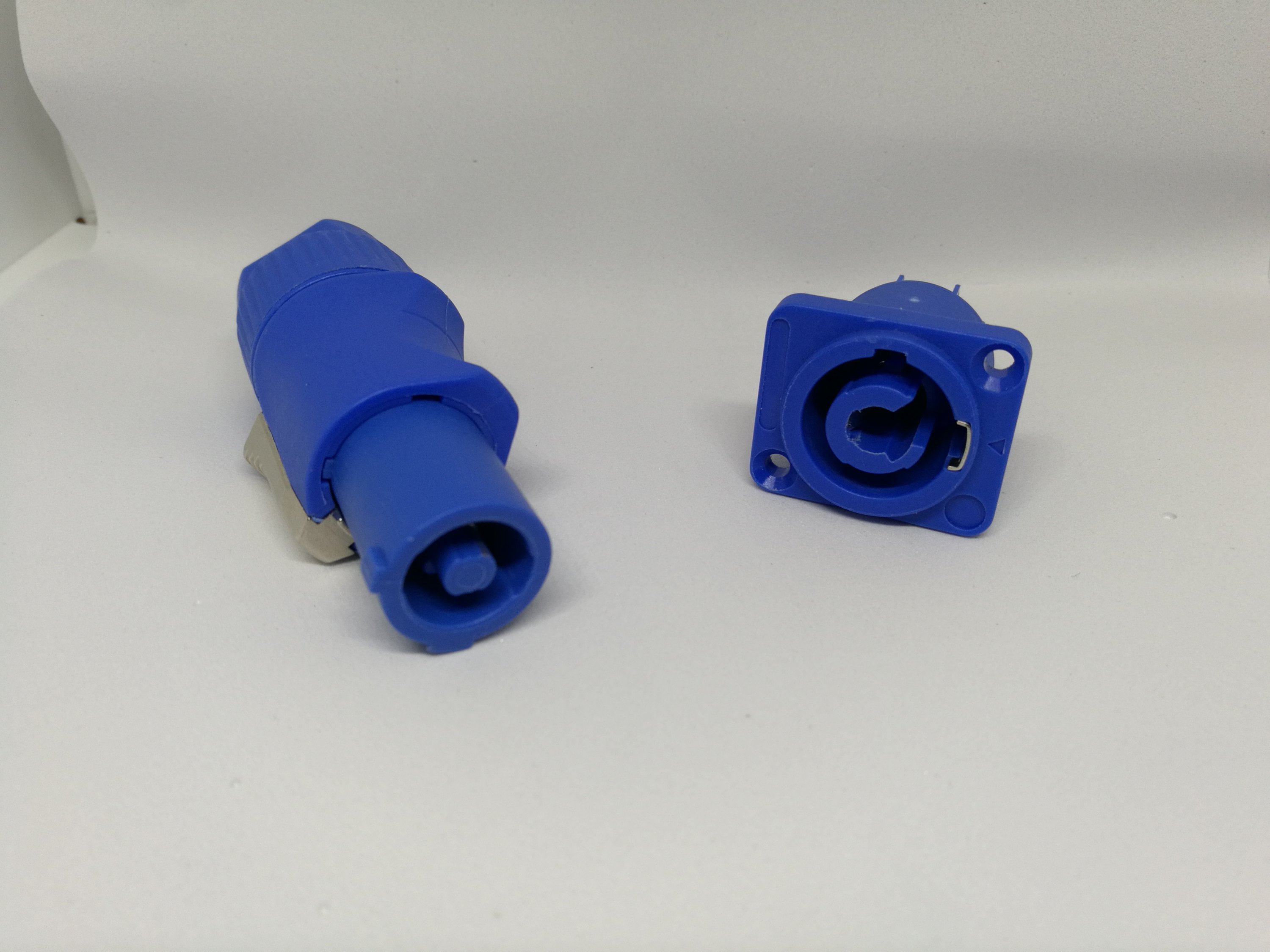

Powercon looks and works similarly to the Speakon: the line connector inserted in the chassis connector and twisted to make contact and lock. Both line and chassis connectors are fully insulated even when disconnected.

The original and most common version of the powerCON is rated at 20 A. It comes in two deliberately incompatible variants (one for power input and other for power output) .The type A is blue and used for power sources (power flows out of a blue-ended cable, into a chassis socket).

The main advantages of the powerCON are high current capacity in a small space and locking. The main disadvantages are cost and reliance on a single vendor. Biggest electrical disadvantage is that powerCON is a connector without breaking capacity, i.e. the powerCON should not be connected or disconnected under load or live! That unfortunately makes them unsuitable for equipment used by untrained personnel.

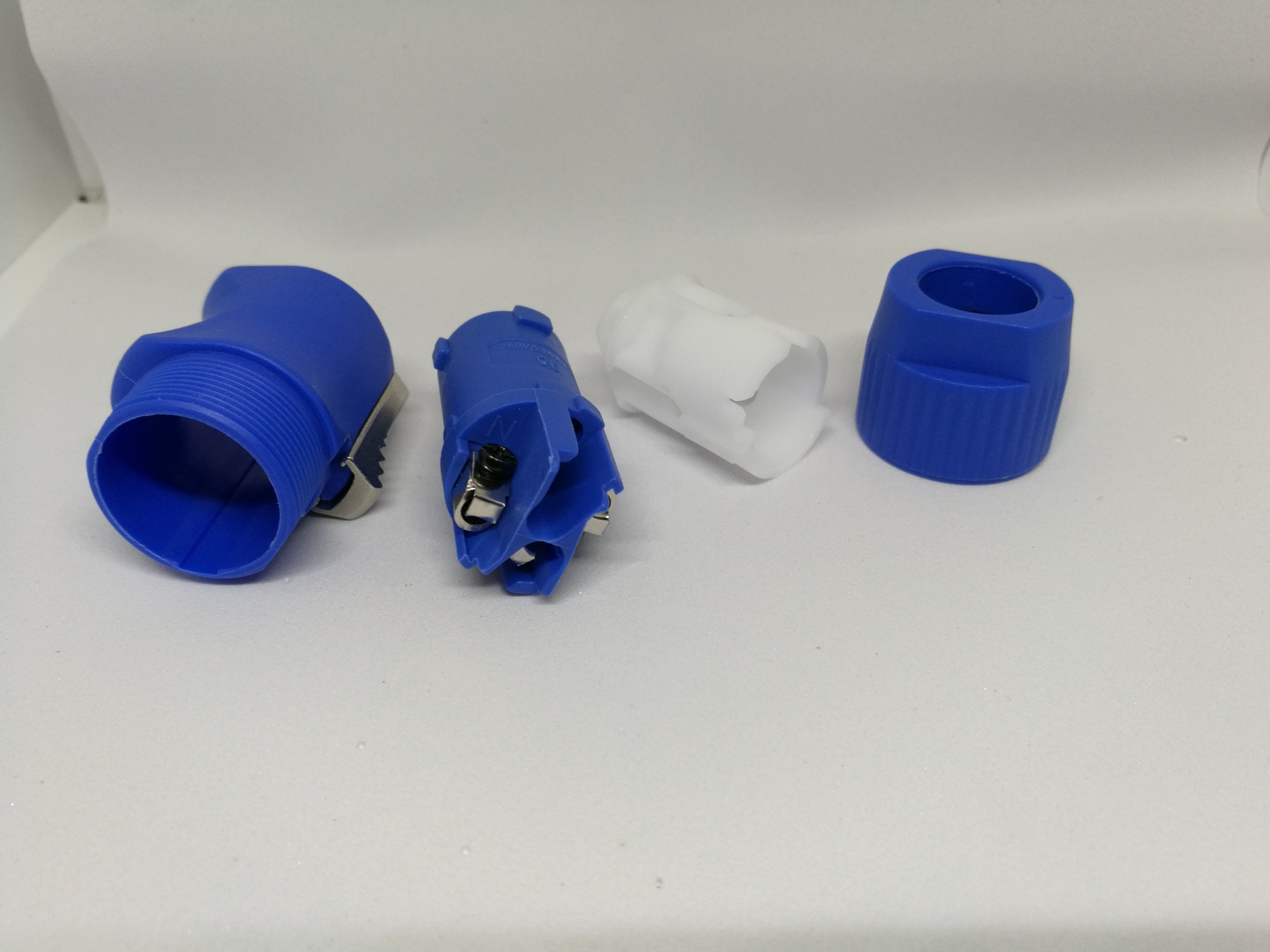

Hare is a powerCON connector I found from Chinese outlet. It seems that we might not be anymore tied to one manufacturer….

It seems that There are lots of non-Neutrik PowerCon connectors, most of which are made in China. While there is some question regarding patent violations, lots of off shore manufacturers make their verison of the PowerCon and also equip sound and lighting products with non-Neutrik versions of the PowerCon. There are ways to spot a counterfeit – and mine looks like one.

Neutrik fights against piracy of products and trademark infringement. Although Neutrik AG is unable to track down and stop all violations of product (patent and trademark infringements), company thinks that it remains an important task on the company’s agenda.

Related connectors

In addition to original powerCON (nowdays known as powerCON 20 A), there are also other connectors nowadays on powerCON product family. Neutrik has introduced a larger 32 A version of the powerCON.

Neutrik announced a new variant of the connector called the powerCON TRUE1.Unlike the traditional PowerCon connectors the new powerCON TRUE 1 connector is specified for disconnection under load. The current rating for it is 16 A and connectors are IP65 rated when mated. powerCON TRUE 1 connector is not compatible with traditional PowerCon connectors.

41 Comments

Tomi Engdahl says:

Fake Neutrik Powercon. August 2015

https://www.aceta.org.au/fake-product.html

The plug breaks if you twist it the wrong way to lock it in place or keep turning once it’s locked. Not much pressure is needed to break it either.

Tomi Engdahl says:

Converting a Surge Protector / Power Strip to Neutrik PowerCON TRUE1 for Daisychainability

https://www.youtube.com/watch?v=lZkdYEErVV8

A guide to adding a Neutrik PowerCON TRUE1 panel connector to a Furman SS-6B power strip to allow daisy-chaining of multiple strips.

Tomi Engdahl says:

How to make a PowerCON cable | Tutorial

https://www.youtube.com/watch?v=WooP4t_LVAY

Tomi Engdahl says:

Neutrik’s powerCON Explained – ISE Show 2016

https://www.youtube.com/watch?v=riy85f8Qov4

Neutrik’s powerCON series includes lockable, extremely robust and reliable 3 pole equipment (AC) connectors.

Neutrik PowerCON TRUE1 – How to install male and female cable connectors

https://www.youtube.com/watch?v=01AnhcF47D4

A helpful guide for installing male and female Neutrik PowerCON TRUE1 electrical connectors onto a cable.

Tomi Engdahl says:

What is Speakon and Powercon Connector in Professional Audio Apllications

https://www.youtube.com/watch?v=bnE6vJdGFaI

Used in Professional audio system for connecting speaker to the audio amplifier. MX Speakon connector is designed with a locking system.

MX Speakon connectors are fully shielded from human touch, preventing electrical shock risks.

Operate in high current, inductive load environment of loudspeakers.

The MX powerCON is a locking 3 conductor equipment AC connector with contacts for line, neutral and pre-mating ground contact. It replaces appliance couplers wherever a very rugged solution in combination with a locking device is needed in order to guarantee a safe power connection.

Tomi Engdahl says:

https://forum.speakerplans.com/powercon-problems_topic93549.html

If you are hot plugging them you are going to have massive issues, and TBH you deserve massive issues, they are clearly marketed as not hot-pluggable and using them to make or break load is moronic.

If you tried that with a 315A camlok you would need new eyebrows…

We know that this type of connector has no breaking capability neither power-on during load.

Your are 100% sure they are Neutrik Powercon, not “another” make?

“Ive found both can suffer from charing on the contacts from being plugged and un plugged when live”

The data sheet on the blue ones I bought said they are not rated for a live line disconnect.

Treat them with De-Oxit when new, no live disconnect, and they should last indefinitely (as mine have for four years).

Tomi Engdahl says:

Topic: Powercon connectors: Breaking capacity?

https://forums.prosoundweb.com/index.php?topic=149840.0

In looking at Neutrik’s information for a 20A connector, which looks like what we need…

Attention: The powerCON is a connector without breaking capacity, i.e. the powerCON should not be connected or disconnected under load or live!

I think I know what this means, but what does it *actually* mean? Can the electricity be on (from the outlet) when plugging the Powercon into a speaker? Should the speaker cabinet be powered off during any time of a Powercon insertion/removal (we’re thinking this is the best approach).

You don’t want the circuit energized and the equipment switched on, or eventually the contacts in the PowerCon will fail. Simply having the circuit energized is OK, since it’s the current being broken that causes the arcing that damages the contacts. I suspect the word “live” is in there just to make absolutely sure there is no chance of current flowing.

I’m not religious about turning the device off before making/breaking the connection unless there’s a significant load – then I will make sure the load is off. A rule of thumb is that if the Edison plug arcs when you plug it (or unplug it) into the receptacle, that load should be turned off before making or breaking the connection, otherwise that arc will happen inside the Powercon, an degrade the connectors, as Geoff mentioned.

its rated for 20 amps of electricity flowing through it when connected.

If memory serves its something small like 1 or 2 amps will burn the contacts off if you keep plugging stuff in with power switches turned on

the powercon true 1 is rated for 16 amps as a disconnect. I believe its their attempt to replace edison and twistloc plugs.

Tomi Engdahl says:

https://en.wikipedia.org/wiki/PowerCon

Tomi Engdahl says:

Safety Note

Neutrik Includes This Safety Instruction With All PowerCon Connectors

https://powerconcables.com/safety-note/

The Powercon system is certified as not having breaking capacity. This term (without breaking capacity) refers to components which in normal use should not be engaged (connected) or disengaged (disconnected) under load or live.

In other words, the device being powered with the PowerCon cable should be in the “off” mode when the connection is made.

The inserting or removing of a PowerCon connector is not a replacement for an on/off switch. Using them in this manner can cause arcing at the terminals which can damage the contacts and possibly cause sparking or excessive heat.

Non-Breaking Capacity? Here’s How To Disconnect A Powercon-Equipped Device

https://powerconcables.com/non-breaking-capacity-heres-how-to-disconnect-a-powercon-equipped-device/

The output version of Powercon connectors are considered “non breaking”, meaning that you should not disconnect (or connect) a piece of equipment with a Powercon while it is in the “on” mode.

In order to correctly power down a device that is not equipped with an on/off switch, you should first disconnect from the power source (unless that end of the cable is also equipped with a Powercon. If both ends of the cable are Powercon equipped, the correct procedure is to shut down the power source before disconnecting the device.

Tomi Engdahl says:

Safety Notice powerCON TRUE1

https://www.neutrik.com/en/news/safety-notice-powercon-true1

https://www.neutrik.com/en/neutrik/products/powercon/powercon-true1

Tomi Engdahl says:

Joke:

Is powerCON named after this type of power con practice?

https://m.imgur.com/gallery/bsnaD

Tomi Engdahl says:

https://www.neutrik.com/en/products/power/powercon-20-a

https://www.neutrik.com/en/products/power/powercon-20-a

https://forums.prosoundweb.com/index.php?topic=149840.0

https://powerconcables.com/test-post-2/

The output version of Powercon connectors are considered “non breaking”, meaning that you should not disconnect (or connect) a piece of equipment with a Powercon while it is in the “on” mode.

In order to correctly power down a device that is not equipped with an on/off switch, you should first disconnect from the power source (unless that end of the cable is also equipped with a Powercon. If both ends of the cable are Powercon equipped, the correct procedure is to shut down the power source before disconnecting the device.

Tomi Engdahl says:

https://www.noretroncomponents.com/powerCON-virtaliittimet/ekauppa/g102040/

https://www.neutrik.com/en/products/power/powercon-true1-top

https://www.neutrik.com/en/neutrik/products/powercon/powercon-true1

Tomi Engdahl says:

Safety Notice – powerCON TRUE 1 July 20181Safety Notice – powerCON TRUE 1

https://www.bromptontech.com/wp-content/uploads/2019/05/PowerCon-True1-SafetyNotice.pdf

This safety notice indicates that in certain circumstances the connector can be inserted incorrectly causing contact between live wires and the grounding contact in the plug socket. Should this occur then the consequences could be serious, resulting in both equipment malfunction and/or personal injury.

Please regularly check the condition of your powerCON TRUE1 connector system (cable connector & chassis) for clear signs of wear and tear.Through improper use and the excessive use of force, the encoding lugs and guide slots in the connector system can become so severely worn or damaged that it is possible to insert the cable connector the wrong way. However, when inserted the wrong way, the cable connector should not twist-lock into place. A cable connector inserted the wrong way could, in some circumstances, lead to contact between live wires and the grounding contact in the plug socket.

To determine that the cable connector is inserted correctly, follow the use instructions and listen for the “click” when performing the twist-lock. Immediately unplug any connector that does not twist-lock correctly in place.

Safety Improvement

With our TRUE1 safety notice we informed about possible contacting between live and earth conductor at wrong insertion of the cable connector. To exclude contacting while wrong inserted certain measures and improvements are in process which is laid down in this paper.

Tomi Engdahl says:

Dont solder powercon connectors

https://forums.prosoundweb.com/index.php?topic=123527.0

I posted this in another thread about powercons, but I feel it deserves its own thread over here. I see many people soldering the connections on powercon connectors. Doing so is not the correct way to use these, and can create a dangerous situation. Read this post all the way through, at the bottom I discuss the proper crimp terminals to use.

NEC ( 250.8 ) prohibits a soldered connection for the ground. It must be a mechanical connection.

“Grounding conductors and bonding jumpers shall be connected by exothermic welding, listed pressure connectors, listed clamps, or other listed means. Connection devices or fittings that depend solely on solder shall not be used. Sheet metal screws shall not be used to connect grounding conductors or connection devices to enclosures”

The instructions for the powercon say to use a 0.187″ crimp terminal. Nowhere in the instructions does it say to solder them. The instructions are part of the UL listing, soldering the terminals on a powercon invalidates the UL listing.

NEC or not, soldering the ground can create a dangerous situation as the joint can heat up (melting the solder and allowing the connection to come apart) during a fault, resulting in energized chassis instead of a breaker blowing.

Powercons should not be soldered, just buy the right crimp terminals and assemble according to the manufacturers instructions.

When selecting the terminal, note the tabs on powercons require a 0.187″ by 0.020″ terminal. The female 0.187″ terminals are available in both .020 and .032 thicknesses. If you buy a terminal with the 0.32 thickness, it will be loose on the powercon. Molex makes 0.187″ x 0.020 female QD terminals which accept 12awg wire. Part numbers are 0190190048 for insulated, and 0190160081 for non insulated.

If these specialty crimp terminals are too difficult to find, I would consider getting a few hundred of them and making them available as a service to the members of this forum if its ok with the mods.

It’s not just the NEC that requires a mechanical ground connection – UL and other regulatory agencies typically do as well.

I contacted Neutrik for an authoritative answer on whether conductors may be soldered to the faston tabs on Powercon connectors. The answer from a product application manager (who checked with factory) is No, conductors may not be soldered to the tabs on a powercon, the proper crimp terminals must be used.

Tim,

You’re missing the point. Soldering speakons is fine. It’s using solder ONLY as the connection for a power ground, such as on a POWERcon, that is not recommended or allowed. If you mechanically fasten the powercon and then add solder, that appears to be allowed. The point is the same as if you soldered together connections in a power panel Shocked

Your crimped failure experience is due to personnel error. people think crimping is simple, but like good soldering, it is a skill to be learned and the right tools must be use.

Mike McNany

I’ve been servicing gear for 30 years. In that time, the number of failed assembly line-made crimps I’ve seen is at least 50 times the number of failed sweat solder joints I’ve seen (and that includes hobbiest made solder joints). The same goes for Fast-On connections. Do as you see fit. If code says to use a method that has been proven to me to be more likely to get someone killed…….

Tomi Engdahl says:

powerCON TRUE1 Cable Connectors

*Discontinued* Please see successor powerCON TRUE1 TOP series. Connectors of both series are fully compatible.

https://www.neutrik.com/en/neutrik/products/powercon/powercon-true1/powercon-true1-cable-connectors

powerCON TRUE1 TOP

https://www.neutrik.com/en/products/power/powercon-true1-top

The highly innovative entertainment industry is permanently evolving accompanied by increasing demands on interconnection systems. Particular environmentally sealed connectors are highly requested for heavy-duty and harsh environment applications of entertainment equipment like PA systems, signs and LED screens or lightings.

Neutrik took up the challenge and developed a new line of TRUE OUTDOOR PROTECTION (TOP) products for demanding outdoor applications. This new range includes the popular powerCON TRUE1, etherCON and XLR series. These ruggedized sealed connectors feature not only IP protection but also UV resistance approved according to UL50E.

Tomi Engdahl says:

https://www.facebook.com/groups/1562990120614822/permalink/3349970261916790/

Best / safest way to terminate these bad boys?

Solder with heatshrink?

Spade connections?

I use spade connectors – ideally ones with plastic over the whole thing if you can fit it, or heat shrink over it after crimping the wire in the connector.

These aren’t really made for soldering; you can melt the plastic casing, and the wires can break off over time

Neutrik faston spade connectors plus glue lined heatshrink over each terminal.

Neutrik make a Powercon boot for covering the rear of the connectors. We always solder the connections and then use the boot to cover it. Never had any problems! We have had a few issues with the crimp spade connectors however. I guess if you soldered to those spades it would be alright though – https://www.neutrik.com/en/product/scdr

+1 for solder with heathshrink

Spades and one large piece of heatshrink over the back of the connector to provide a little strain relief

Tomi Engdahl says:

https://www.neutrik.com/en/product/nac3mpa-1-wot

NAC3MPA-1-WOT

Chassis connector, power-in, 3/16” flat tab terminals, blue, without insulation divider

The powerCON is a locking 3 conductor equipment AC connector with contacts for line, neutral and pre-mating ground contact. It replaces appliance couplers wherever a very rugged solution in combination with a locking device is needed in order to guarantee a safe power connection.

Attention: The powerCON is a connector without breaking capacity, i.e. the powerCON should not be connected or disconnected under load or live!

Features & Benefits

Locking 20 A / 250 V ac appliance coupler

3 contacts for line, neutral and premating safety ground

Power-in (blue) and power-out (grey) versions with different keying to avoid the possibility of intermating

Fast and easy twist lock latching system

Extremely robust and reliable

Ergonomic design

User friendly latch design for easy handling

UL, cUL recognized components

VDE certified

Tomi Engdahl says:

https://www.canford.co.uk/Products/42-0391_NEUTRIK-NAC3MPXXA-WOT-POWERCON-Mains-input-panel-connector-20-Amp

Note 1:- Cable connectors will only mate with their corresponding panel connector type. e.g. Mains Input cable connectors will only mate with Mains Input panel connector (both blue). Mains Output cable connectors will only mate with Mains Output cable connectors (both grey).

Note 2: Neutrik Powercon connectors are certified to the IEC 62368-1 standard which is defined as “appliance couplers for household and similar general purpose”. If these connectors are required for use in a building installation, the installer must ensure that the necessary protective measures and applicable standards are complied with. This series of connectors can be used in an application such as a building installation, but Neutrik cannot offer certification or declaration of conformity for this use.

Tomi Engdahl says:

4.8 ×0.5mm

NEUTRIK POWERCON AC MAINS POWER CONNECTORS – 20 Amp

Cable connectors have screw terminals (max. wire size 4mm), panel connectors have ‘Faston’ 4.8 ×0.5mm ‘spade’ terminals.

Tomi Engdahl says:

https://forums.prosoundweb.com/index.php?topic=123527.0

Dont solder powercon connectors

« on: February 03, 2010, 12:02:31 AM »

I posted this in another thread about powercons, but I feel it deserves its own thread over here. I see many people soldering the connections on powercon connectors. Doing so is not the correct way to use these, and can create a dangerous situation. Read this post all the way through, at the bottom I discuss the proper crimp terminals to use.

NEC ( 250.8 ) prohibits a soldered connection for the ground. It must be a mechanical connection.

“Grounding conductors and bonding jumpers shall be connected by exothermic welding, listed pressure connectors, listed clamps, or other listed means. Connection devices or fittings that depend solely on solder shall not be used. Sheet metal screws shall not be used to connect grounding conductors or connection devices to enclosures”

The instructions for the powercon say to use a 0.187″ crimp terminal. Nowhere in the instructions does it say to solder them. The instructions are part of the UL listing, soldering the terminals on a powercon invalidates the UL listing.

NEC or not, soldering the ground can create a dangerous situation as the joint can heat up (melting the solder and allowing the connection to come apart) during a fault, resulting in energized chassis instead of a breaker blowing.

Powercons should not be soldered, just buy the right crimp terminals and assemble according to the manufacturers instructions.

When selecting the terminal, note the tabs on powercons require a 0.187″ by 0.020″ terminal. The female 0.187″ terminals are available in both .020 and .032 thicknesses. If you buy a terminal with the 0.32 thickness, it will be loose on the powercon. Molex makes 0.187″ x 0.020 female QD terminals which accept 12awg wire. Part numbers are 0190190048 for insulated, and 0190160081 for non insulated.

It’s not just the NEC that requires a mechanical ground connection – UL and other regulatory agencies typically do as well.

As far as those Molex connectors go, they are rated for 12-14AWG, not 10-12. As an aside (assuming that someone at Neutrik still reads this forum), how many of us would be willing to pay a couple bucks more for a Powercon or Speakon if it came with the appropriate crimp connectors?

Re: Dont solder powercon connectors

« Reply #5 on: February 03, 2010, 11:41:15 AM »

Tim,

You’re missing the point. Soldering speakons is fine. It’s using solder ONLY as the connection for a power ground, such as on a POWERcon, that is not recommended or allowed. If you mechanically fasten the powercon and then add solder, that appears to be allowed. The point is the same as if you soldered together connections in a power panel Shocked

Your crimped failure experience is due to personnel error. people think crimping is simple, but like good soldering, it is a skill to be learned and the right tools must be use.

Tomi Engdahl says:

IKEA small power connector

https://www.ikea.com/fi/fi/p/askvaeder-aloitussarja-4-osaa-50486711/

Tomi Engdahl says:

https://www.harmonycentral.com/forums/topic/191268-what-is-the-measurement-of-a-d-hole/

23.8 mm is the size of the cutout shown for the Neutrik male pass-thru adapter. The Audiopile website for that item has the technical drawings with the dimensions. (Sorry I can’t figure out how to use the iPhone to add the link for you.) Mark C.

Tomi Engdahl says:

PLUG IN – Episode 12 – Let’s talk REAN X series

https://www.youtube.com/watch?v=bqJT3BkrcwQ

The REAN X series offers an alternative AC power connector series that is fully compatible with NEUTRIK’s industry-standard powerCON® TRUE1® TOP. REAN power X is IP65 when mated and manufactured using UL 94 V-0 materials.

Tomi Engdahl says:

Neutrik’s powerCON series includes lockable, extremely robust and reliable 3 pole equipment (AC) connectors.

The main advantages of the powerCON are high current capacity in a small space (smaller than an IEC connector and double the current-carrying capacity) and locking action. The main disadvantages are cost and reliance on a single vendor.

The powerCON is a lockable equipment AC connector. It’s used in the audio business for the power lines of lighting applications, amplifiers, etc. It can be used as power supply for industrial applications with the advantage of its locking system in comparison to standard non locking MAINS* connectors.

Tomi Engdahl says:

What cable is used for PowerCon?

The cable utilizes standard duty cord with 3 conductors with cross section 1.5 mm2 or AWG 12.

Tomi Engdahl says:

What is the difference between PowerCon and PowerCon true?

The fundamental difference between PowerCon and PowerCon TRUE1 is that TRUE1 is rated for make and break under load, while standard PowerCon is not. The two connectors are not intermateable.

The powerCON TRUE1 is a locking waterproof 16 A true mains connector.

Tomi Engdahl says:

What is the difference between blue and GREY powerCON?

The blue plug is the voltage-carrying plug, i.e. the one that is plugged into the voltage input of a device, while the grey plug is the voltage-receiving plug for the output of a device (i.e. for passing on voltage).

Tomi Engdahl says:

https://powerconcables.com/counterfeit-connectors/

While there is some question regarding patent violations, lots of off shore manufacturers make their verison of the PowerCon and also equip sound and lighting products with non-Neutrik versions of the PowerCon.

Tomi Engdahl says:

Many versions of other manufacturers connectors use a metallic or metallic looking spring loaded locking tab. The current version of the true Neutrik PowerCon uses a yellow locking tab.

True PowerCon connectors say “Neutrik” right on the connector body. While the “patentability” of the connector may be in question, the use of the Neutrik trademark is not.

Tomi Engdahl says:

Most non-Neutrik PowerCons are fully compatible with the real thing, but care should be taken to insure that a manufacturers failure to pay attention to detail may well create a safety hazard when these connectors are used

https://powerconcables.com/counterfeit-connectors/

Tomi Engdahl says:

At the end of 2020, Neutrik released a re-designed version of the original PowerCON which is capable of connecting/disconnecting under load when mated with the corresponding connectors. Cable connectors with breaking capacity are recognizable due to the ‘-1′ in their article number like NAC3FCA-1. Appliance connectors are recognizable due to the ‘XX’ added in their article number like NAC3MPXXA.

In January 2011, Neutrik announced a new variant of the connector called the powerCON TRUE1.

https://en.m.wikipedia.org/wiki/PowerCon

Tomi Engdahl says:

https://www.facebook.com/groups/Indysoundtechs/permalink/6588890514526040/

Update:

Neutrik called me back within an hour and confirmed they are reverse compatible and yes it’s different plastic and thickness but the connection tolerances are the same

——————

Hey guys! Does anyone have an experiance with new style PowerCON connectors? (Not to be confused with True1) NAC3FCB has been discontinued

I am wiring up some output ends for some jumpers and the new style seems to have a thinner ring. The tolerance of the pins seems very close if not identital but just concerned about not having a solid fit. I tried them on some lights and they work fine.

This is what am using

https://www.neutrik.com/en/product/nac3fxxb-w-l

Thanks!!

Tomi Engdahl says:

https://www.neutrik.com/en/product/nac3fxxb-w-l?fbclid=IwAR2ofx5pW24ZtlyL0Wk20V9SZm85j0PE8JWpkWLVgBeJ_R08sw0PIIvfZH0

NAC3FXXB-W-L

IEC EN 60320-1 compliant | Accepted for cord sets as per IEC EN 60799:2021

Locking AC mains cable connector, keyed and color coded (grey) for power-out, screw terminal assembly, for cable diameters 10 – 16 mm.

The powerCON FXXA/FXXB is a single phase (3 conductor) lockable power connector with Circuit Breaking Capability when mated with powerCON XX Series receptacles.

It replaces appliance couplers wherever a very rugged solution in combination with a locking device is needed to guarantee a safe power connection.

Tomi Engdahl says:

https://www.neutrik.com/en/news/neu-powercon-xx-iec-60320-1-konform

“The new NAC3FXX-A and -B are compliant with all relevant versions of the 60320-1 standard. This is a mandatory requirement for use on equipment connection cables in accordance with IEC EN 60799, which applies to the event sector, among other things. Directive-compliant power cables in this area must therefore be equipped with power connectors certified to IEC EN 60320-1.”

Tomi Engdahl says:

Blue Powercon ist for AC power in only. For power out the powercon connector is grey/white.

These 2 are the basic parts for the powercon system and they are design so they dont fit together for the same reasons that any other power connector system is designed to have different input and output connectors so they cant be used the wrong way without an idiot building the equipment and cables the wrong way around (like in this case).

Tomi Engdahl says:

https://www.blue-room.org.uk/topic/74424-opinion-on-alternative-powercon-brands/

Tomi Engdahl says:

https://www.reddit.com/r/VIDEOENGINEERING/comments/17e0yiv/does_anyone_know_the_name_of_this_power_connector/

The blue powerCON are the biggest mistake ever, you can’t connect or disconnect then while powered. The way the connection points are designed it will arc and eat away the contacts ending in breakers getting tripped.

Tomi Engdahl says:

Schuko® vs. powerCON® vs. TRUE 1®

https://www.cordial-cables.com/en/world-of-cordial/wiki/powercon

Electricity at events is always a tricky subject. Whether Schuko®, powerCON®, TRUE 1® or TRUE 1® TOP, the right plug (and the corresponding cable) is optimized depending on the intended use. But what is the difference between those plugs?

With the powerCON® plug, NEUTRIK® has developed a lockable standard of cold appliance connectors for event technology. The plugs are more robust and space-saving than normal Schuko® plugs and can be loaded up to 20A. The blue plug is the voltage-carrying plug, i.e. the one that is plugged into the voltage input of a device, while the grey plug is the voltage-receiving plug for the output of a device (i.e. for passing on voltage). To avoid confusion, the plugs (and their corresponding sockets) have been designed differently. The protective contact was not designed as “leading”, therefore a powerCON® plug was not allowed to be plugged in under load and voltage. The powerCON® system was therefore not a plug-in device, but a plug-in connection. NEUTRIK® has eliminated this flaw and introduced a further development in the form of the NAC3FCA-1 or NAC3FCB-1 connectors, which may also be plugged in under load and voltage as long as the likewise newly developed sockets NAC3MPXXA, NAC3MPXXA-WOT as well as NAC3MPXXB, NAC3MPXXB-WOT are used.

The powerCON® system is the most widely used power system in the event sector. Our power assembly is therefore also available with the further developed powerCON® plugs. It has no “leading design”, therefore a powerCON® plug must not be plugged under load and voltage. Thus, the powerCON® system is not a connector system, but a plug connection.

To allow connecting power cables while carrying loads and voltage, NEUTRIK® has developed the powerCON® TRUE 1®, which, in contrast to the powerCON® system, is a connector system. This means it can also be plugged under load and voltage due to its design, but at the same time, it offers the advantage of a space-saving design. To prevent confusion, it is not compatible with the standard powerCON® system. Also, it can only be loaded up to max. 16 A.

However, TRUE 1® still offers one more benefit from the Schuko® system: The two plug types are designed as male and female and can therefore be plugged into each other without an adapter, for example, to extend a cable.

To withstand harsher environments and weather conditions, NEUTRIK® has further developed the TRUE 1® plug. The TRUE 1® TOP (TOP = “True Outdoor Protection”) is not only dust and water-resistant when mated (according to IP65, IP = “Ingress protection”), but also UV resistant according to UL50e. Just like their forerunner, they can be loaded up to 16A. The TRUE 1 TOP® is compatible with the TRUE 1® plug

Tomi Engdahl says:

https://youtu.be/q3z0qxuWTys?si=rXbnkLD5e_YGOg66

Tomi Engdahl says:

Original PowerCon is not designed to be plugged or unplugged when there is power flowing through the connector – can cause sparks inside connector and damage. The original mains outlets can handle plugging and unplugging OK no matter if there is current flow or not.

Powercon True 1 handles plugging and unplugging somewhat better.