A cable tie (also known as a hose tie, zip tie, or by the brand name Ty-Rap) is a type of fastener, for holding items together, primarily electrical cables or wires. The most common cable tie consists of a flexible nylon tape with an integrated gear rack, and on one end a ratchet within a small open case.

Because of their low cost and ease of use, cable ties are ubiquitous, finding use in a wide range of other applications. And one such strange cable tie use is shown in this picture posted to the Facebook to

https://m.facebook.com/story.php?story_fbid=583323155646163&id=124628051515678

This this shows a very questionable way to join two wires. Here instead of reliable join (like proper screw or crimped connector or soldering) was made by just squeezing two bare wires together just zip tie.

This does not look proper or safe way to join cables. But does this work well and how unsafe it this? Has anyone tested what is the current this kind of hack melts away?

The discussion started and quick Google searching did not reveal immediate answer, so I thought I might to do some testing.

There were comments “Tomi Engdahl I was just going to ask the same thing…. if the surface area of contact is roughly the same as the conductor and the zip tie is pulled tight…. it should work? What do you think?” which lead to conclusion that I have to do some testing myself at this point to get this issue sorted out. I started to find this theme interesting.

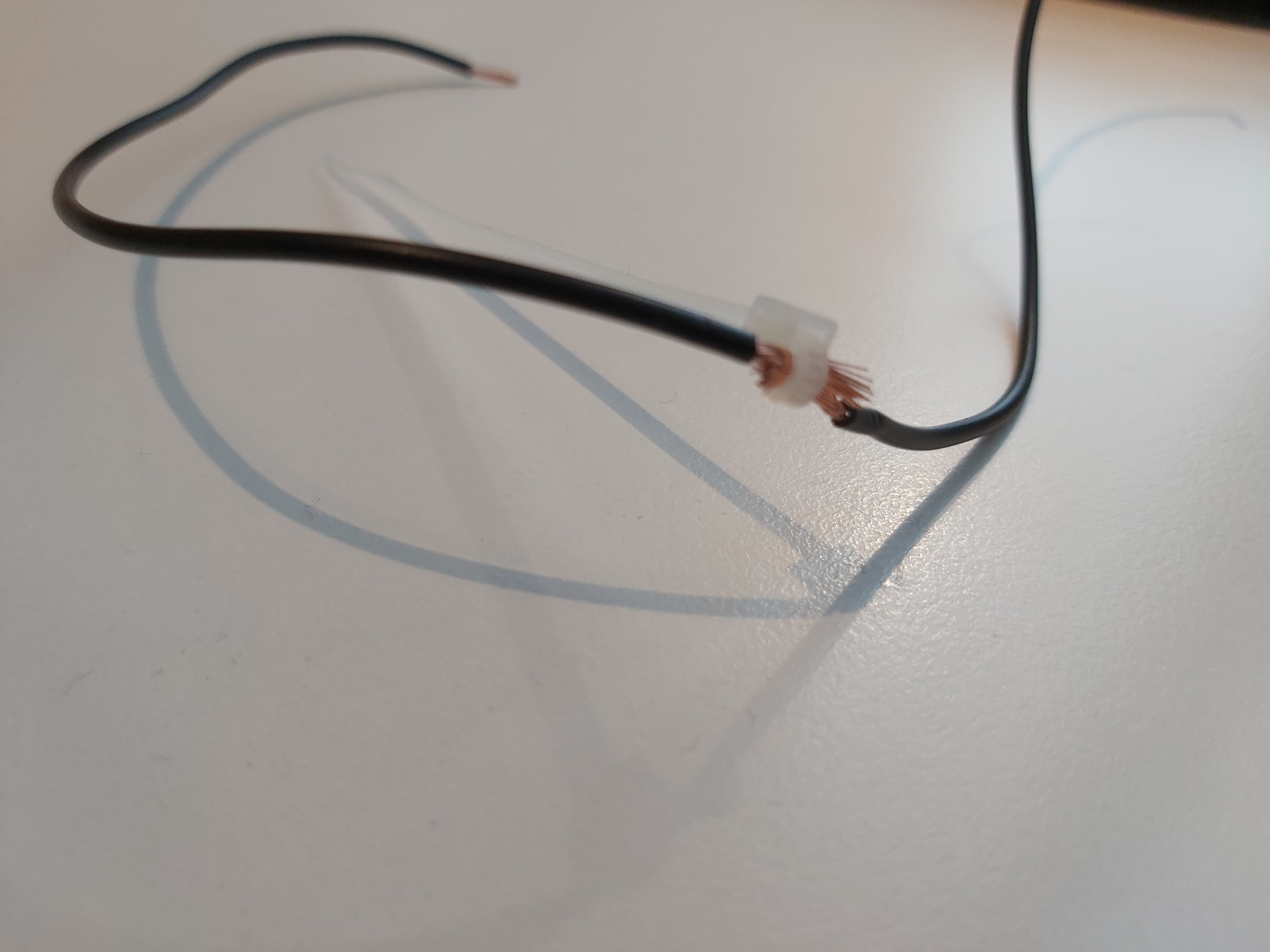

I did a quick test. I made a test joint with two 0.75 mm2 wires connected with small zip tie.

After several minutes at 5A DC load current no considerable heating compared to cable. I stopped testing because it did not lead to any conclusions.

Maybe I need to test with higher current and maybe longer time to get comparative results?

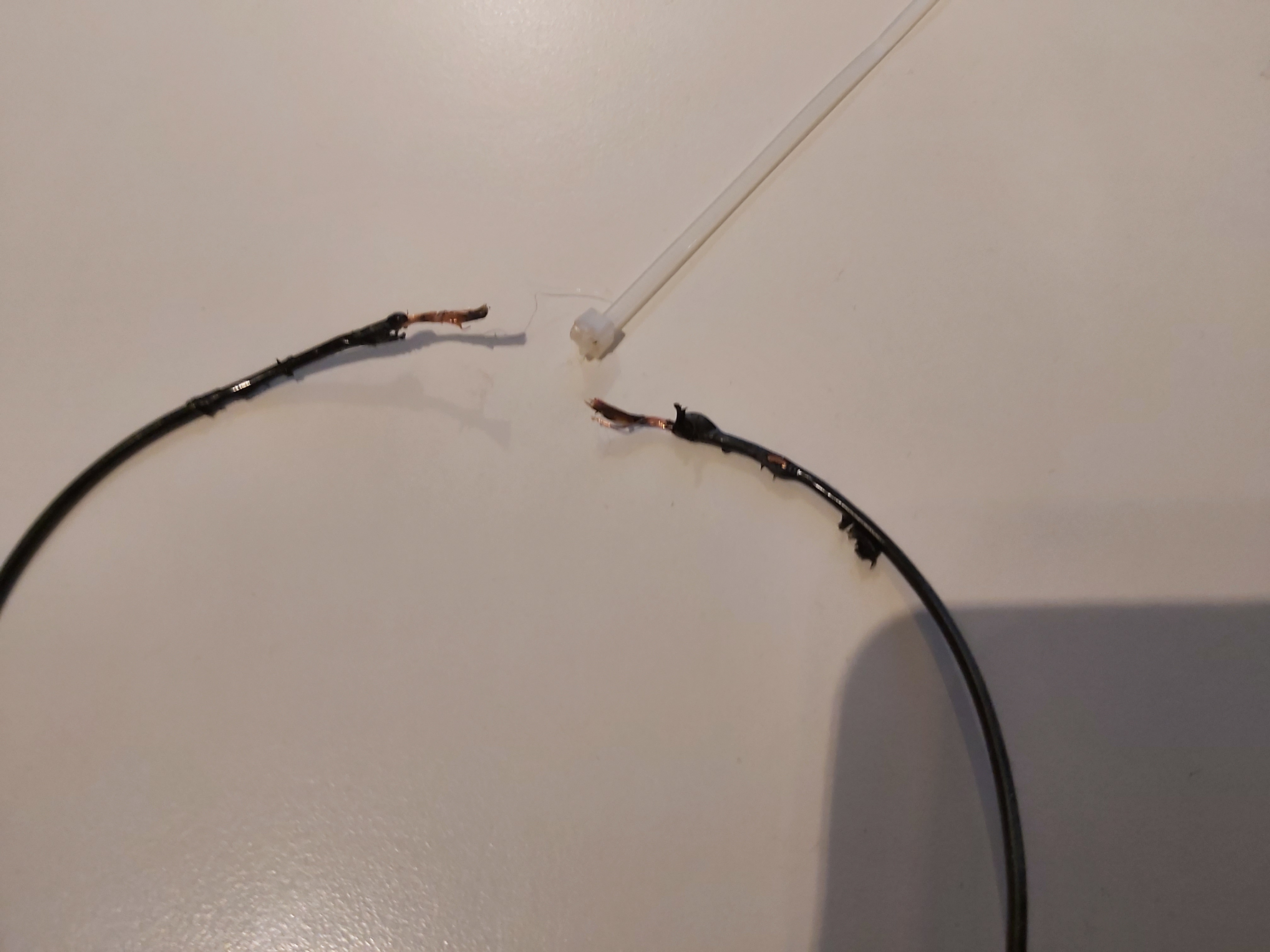

When I overloaded the same cable setup with 20-28A AC current, things worked some time OK.

Then after minute or so the the wires heated so much that insulating PVC plastic on them seemed to become soft and melting, the zip tie quite quickly melted opening the wire joint with some sparking before any smoke started to come out from wire insulation. So the zip tie failed before the insulation started to melt off.

Finally check some technical data like in “proper engineering method” where you first test and then read the manual last.

The common cable tie is normally made of nylon. One manufacturer says “Ties withstand temperatures to 185°F (85°C) and have a melting point of 495°F (257°C)“. The cable insulation was believed to be made of Polyvinyl chloride (PVC) that has Glass Transition Temperature 82 °C (180 °F) and Melting point 100 °C (212 °F) to 260 °C (500 °F). So the melting point of insulation and the zip ties are around in the same range.

I do not recommend zip ties to use to join cables. They are not designed for that and this type of joints are not safe. I expected the zip ties connection to be a bigger disaster than it turned to be, so it worked somewhat better than I expected, but not well enough to be trusted for any real uses. Keep thing safe use the right job for the task. Use zip ties to only keep the wires and cables together and in the right place. Use proper connectors to connect wires together.

12 Comments

Tomi Engdahl says:

Even the Mars Rover Uses Zip Ties

If they’re good enough for NASA, then who cares if your Civic has one or 10? Or 100?

https://www.thedrive.com/tech/39426/even-the-mars-rover-has-zip-ties

Tomi Engdahl says:

How to avoid a CABLE TIE NIGHTMARE – Electricians’ tips and tricks #shorts

https://www.youtube.com/watch?v=HzJAAqlTkAk

The sinking feeling as you drop a bag of cables ties (zip ties) and they spill out of the bag. With this simple electricians’ tip, you can avoid the problem.

Also great for other bagged items – ferrules, crimps, nuts and bolts.

Tomi Engdahl says:

Nylon 6/6, the grade most often used for cable ties, meets UL 94 V-2 flammability ratings and has a working temperature range from -40°C to 85°C. Nylon cable ties can be heat stabilised for continuous or extended exposure to high temperatures of up to 121°C.

https://www.essentracomponents.com/en-gb/news/guides/a-guide-to-cable-ties

Tomi Engdahl says:

Best Zip Tie Brand (7 Brands Tested)? Let’s find out!

https://m.youtube.com/watch?v=SY2Ee-1yuuQ

Tomi Engdahl says:

https://www.advancedcableties.com/cable-management-solutions/act-proud-member-nema/nema-cable-tie-type-classifications/

Tomi Engdahl says:

https://www.cabletiesandmore.com/heavy-duty-zip-ties

Tomi Engdahl says:

https://hackaday.com/2023/01/05/excuse-me-your-tie-is-unzipped/

Tomi Engdahl says:

https://www.essentracomponents.com/en-us/news/solutions/wire-cable/a-guide-to-cable-ties

What are cable ties used for?

Also known as zip ties, they’re fasteners that bundle your cables and wires together to keep them organized and prevent damage. They come in different sizes, lengths, materials and even colors. The different uses of cable ties vary across industries, but what they all have in common is that they’re the most effective way to manage your cables.

When were zip ties invented?

They’ve been around since 1958. Who invented zip ties? Scottish-born Maurus C. Logan, who worked at Thomas & Betts. He got the idea while touring an aircraft facility, noticing how difficult and complex the job of wiring was. It involved thousands of feet of cabling manually secured with knotted, wax-coated, braided nylon cord, leaving the workers’ hands with deep cuts and callouses. This is an example of a simple invention having a profound effect on lives.

When were cable ties invented?

They’ve been around since 1958. Who invented cable ties? Scottish-born Maurus C. Logan, who worked at Thomas & Betts. He got the idea while touring an aircraft facility, noticing how difficult and complex the job of wiring was. It involved thousands of feet of cabling manually secured with knotted, wax-coated, braided nylon cord, leaving the workers’ hands with deep cuts and callouses. This is an example of a simple invention having a profound effect on lives.

Standard cable ties are a fantastic all-rounder, but when you need something more specialized, such as heat-proof cable ties, industrial-strength cable ties, or solutions with excellent resistance to UV rays, you can get those too.

Nylon Cable Ties – will zip ties melt?

Nylon produces a high-strength zip tie with good thermal and abrasion resistance. It also resists fuels and most chemicals. Nylon 6/6, the grade most often used for cable ties, meets UL94 V-2 flammability ratings and can operate in temperatures as low as -40°F. Typically, a nylon zip-tie melting point is 185°F.

Nylon cable ties can be heat stabilized for continuous or extended exposure to high temperatures of up to 250°F. The manufacturing process can also produce UV stabilized ties for outdoor use. For example, you can have the same cable tie, but manufactured for different applications.

Polypropylene

If you’re looking for chemical resistant cable ties, consider polypropylene (PE). It resists acids, polyhydric alcohols, neutral salts and basic salts, making it a better choice in this instance than nylon. It does have a lower tensile strength than nylon 6/6, but it’s also more flexible. Polypropylene can also stand up to UV exposure.

Just as you can get the same cable tie formulated differently, you can get the same cable tie in different materials. For example, beaded cable ties are available in nylon or polypropylene.

Low density polyethylene – ideal as temporary zip ties

Low density polyethylene (LDPE) has a high-ductile nature and less-than-average tensile strength. As a material for cable ties, it’s not commonly used. However, it stretches and conforms well to surfaces and has excellent chemical resistance to dilute and concentrated acids, alcohols, bases and esters, so it has its uses. For these reasons, it’s often used for ties that are meant to bundle cables temporarily.

Stainless Steel – high-temp zip ties

Stainless steel cable ties provide high tensile strength. They can also stand extremely high temperatures, from –328°F to 1000°F. There are two types of stainless steel used in cable ties: 304 and 316. Type 304 is used for general purposes, with both indoor and outdoor applications. When corrosion is a threat, it’s Type 316 you need.

Aerospace

The average passenger airplane wields 124 miles of cables, so excellent cable management is absolutely critical. The types of cable ties needed vary. For small, tight spaces, miniature heat-stabilized cable ties are a must. For hoses and larger cables, heavy duty heat stabilized cable ties are needed. Push mount cable ties also work well for aerospace and it’s best to go with a heat-stabilized option for thermal endurance.

Automotive

If your cable ties are going under the hood, chemical and heat resistance should be your priority. In addition to standing up to oil, greases and gasoline, your cable ties should also be able to withstand harsh environments.

Consider push mount cable ties made of heat-stabilized nylon 6/6, rated UV94 V-2, and serviceable to 239˚F. Stainless steel cable ties also offer excellent resistant to high temperatures and weathering.

Other cable ties for automotive applications include standard cable ties and screw or adhesive cable tie mounts, and arrow head cable ties.

Equipment manufacturing

Industrial generator parts and HVAC components vibrate. If your application is indoors, screw mount cable ties are the ideal solution. Fir-tree mount cable ties add additional stability against vibrations, while providing protection against debris ingress.

For outdoor applications, you need cable ties that can stand up to the weather and a range of temperatures. Weather-resistant standard cable ties work well. You’ll need a heat resistant cable, of course. For this, heat-stabilized cable ties, which also perform in extreme cold weather are the ideal complement.

Consumer appliances and electronics

You’re working with limited space and will need cable ties that resist heat. This goes for consumer electronics too. An excellent choice in these conditions is an arrow head cable tie. Simply push it into your pre-drilled hole. Also look at heat stabilized cable ties. These are exceptionally strong with the additional benefit of being cost effective. Vinyl-coated adjustable clamps are actually ties and combine fantastic flexibility with secure mounting.

Enclosures and cabinets

An indoor data cabinet can fall victim to cable spaghetti, which happens when cables become one big mess. Standard cable ties, which come in different colors for color coding, can prevent this. Marker cable ties can also prove helpful, allowing you to write identification information on a tag attached to the cable. Beaded cable ties are another option. You can link them together to get your desired length and some are reusable.

For an outdoor utility cabinet or any outdoor cable enclosure, UV resistance is important. Weather-resistant cable ties are an ideal solution. Beaded cable ties can work here too, if they’re UV resistant. For heavy duty applications try strap and buckle ties or stainless steel cable ties.

Tomi Engdahl says:

https://www.essentracomponents.com/en-us/news/solutions/wire-cable/a-guide-to-cable-clips

Tomi Engdahl says:

https://www.essentracomponents.com/en-us/news/solutions/general-protection/a-guide-to-hose-clamps

Tomi Engdahl says:

https://www.essentracomponents.com/en-us/news/solutions/wire-cable/the-ultimate-guide-to-cable-management

Tomi Engdahl says:

Cable Ties Strength Chart

https://www.justcableties.co.uk/cable-ties-strength/

Black And Natural Nylon Cable Ties

The weight our Nylon cable ties can carry is indicated by their Tensile Strength rating. Generally, the wider the cable tie the higher the Tensile Strength.

When planning your requirements you should use the Tensile Strength of the cable ties you intend to use to give an indication of how many ties are needed to hold the required weight safely. We advise you always use more than the minimum number required.

Tensile Strengths

80mm x 2.5mm 8kg

All other 2.5mm 8.1kg

All 3.6mm wide 18.2kg

All 4.8mm wide 22.2kg

All 7.6mm wide 54.4kg

All 9mm wide 79.4kg

All 12.7mm wide 114kg