Any form of energy, when not properly controlled or harnessed, can result in serious danger to those who use it. Electricity at any voltage can be dangerous and should always be approached with caution. Direct Dangers of Electricity include a variety of hazards that include Electric Shock, Physical Burns, Neurological Damage and Ventricular fibrillation resulting in death. The indirect dangers of electricity include for example fall due electric shock, an explosion, or a fire.

Electric Current affects the body when it flows through. Human can feel around about 1 milliampere (mA). The current may cause tissue damage or heart fibrillation if it is sufficiently high. 10-20 mA is beginning of sustained muscular contraction (“Can’t let go” current) and 30 mA can cause the onset of potentially fatal respiratory paralysis. A low-voltage (110 to 220 V), 50 or 60-Hz AC current travelling through the chest for a fraction of a second may induce ventricular fibrillation at currents as low as 60mA.

Today’s U.S. electricity system is a complex network of power plants, transmission and distribution wires, and end-users of electricity.

Electrical safety is the leading subject in the North American power industry, but at home people in USA are stuck with a 100+ year old plug design that is far behind other countries in terms of safety features.

ARE AMERICAN PLUG SOCKETS DANGEROUS? video gives some observations about the differences between the UK and US electrics and fire safety:

“Each year, approximately 2,400 children suffer severe shock and burns when they stick items into the slots of electrical receptacles. It is estimated that there are six to 12 child fatalities a year related to this.”

I guess that data makes me wonder about those who say they are safe.

Perhaps the weakest link in the US electrical system video gives on overview of dangers of electrical outlets and extension cords.

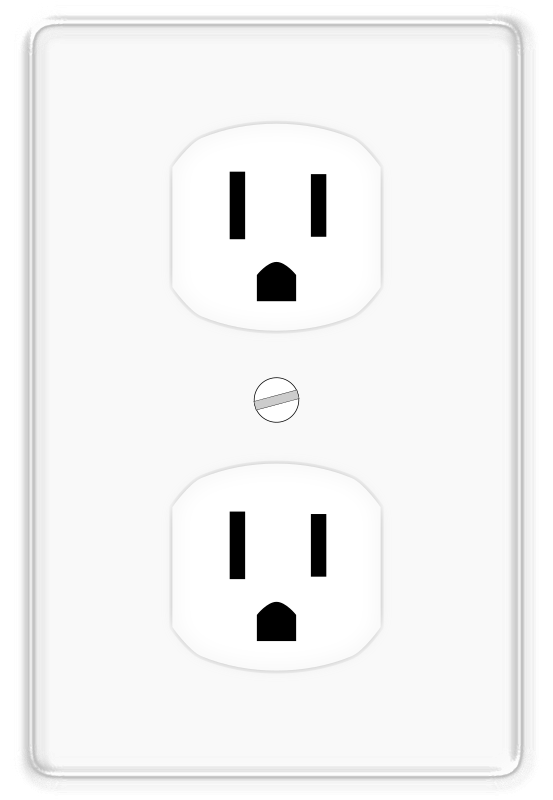

Most of North America (and Central America, and some of South America) use connectors standardized by the National Electrical Manufacturers Association. Those connectors are called NEMA connectors.

NEMA 1-15 ungrounded (Type A) plugs have two parallel blades and are rated 15 A at 125 volts. They provide no ground connection but will fit a grounding NEMA 5-15 receptacle. Ungrounded NEMA-1 outlets are not permitted in new construction in the United States and Canada, but can still be found in older buildings. You can shock yourself with many USA NEMA connectors if you just slipped around the end at the wrong moment. That is the original plug from the very early 20th century… It couldn’t be changed later because there were too many NEMA-1 outlets in service.

NEMA 5-15 grounded (Type B) plug has two flat parallel blades like NEMA 1-15, and a ground (earth) pin. It is rated 15 A at 125 volts. The National Electrical Contractors Association’s National Electrical Installation Standards (NECA 130-2010) recommends that sockets are mounted with the ground hole up so that a falling object makes first contact with the ground pin. This socket is recommended in IEC standard 60906-2 for 120-volt 60 Hz installations. NEMA 5-15 grounded (Type B) sockets accepts also NEMA 1-15 ungrounded (Type A) plugs. In stage lighting, this connector is sometimes known as PBG for Parallel Blade with Ground, Edison or Hubbell. “Typical” 120v receptacles are protected with 15A breaker. This protects the outlet against overload.

Starting with the 2008 Edition of the NEC (National Electrical Code) the NEC has required tamper-resistant receptacles be used in certain locations. The NEC has been increasing the requirement for receptacles to be tamper-resistant with the revisions after that.

Tamper-resistant receptacles work by having a plastic shutter in front of where the plug gets inserted, which is only moved out of place if objects are placed into both slots of the receptacle TR-rated outlets feature “TR” engraved into the outlet faceplate, typically between the two prongs. The shutters remain closed until the proper plug is inserted. This ensures that items like knives, forks, or loose jewelry are not able to access plugs, thus reducing electrical shock injury.

Nothing is safe. There are only degrees of safety. None of these designs can always prevent a determined or negligent person from electrocuting themselves.

There are some people that think that TR Tamper Resistant Outlets Suck

There are also higher current than 15A outputs in use in USA, but a general-use receptacle cannot be on any circuit larger than 20 amps. The NEMA 5-20 AP variant has blades perpendicular to each other. The receptacle has a T-slot for the neutral blade which accepts either 15 A parallel-blade plugs or 20 A plugs. The NEMA 5-20 AP wall socket can accept both 20A plug and 15A plug.

While normal electrical outlets in USA output 120V AC, that’s not the whole story and the voltage the power distribution to most houses work. The distribution voltage is normally the sum of the two 120V lines that are are at opposite phase (180 degree phase shift) plus neutral wire. But in some cases power can come from two 120V lines that have 120 degrees phase shift (some locations which use certain type of three phase power feed). Learn about the US electrical system in this The US electrical system is not 120V video:

US electrical system uses circuit breakers as wiring and fire protection. Circuit breakers are there to stop the cable in the walls of your house melting and possibly catching fire – circuit breakers and fuses perform the function of stopping a fire (which of course is also very dangerous to life). Standard circuit breakers shut off power when the current is too high, like 10, 15, or 20 amps, but a mere 0.030 amps through a body can cause paralysis of skeletal muscles and stop the human heart.

If you are at new house built according current code, you are likely to have also GFCI or AFCI designed trip before anything bad happens. GFCI can protect in many cases against human touching live wire and ground at the same time. But GFCI does not provide protection in all cases, for example if you have your finger between live and neutral contacts on mains plug. AFCI is designed trip if there is arching on the wiring like bad contact, loose wire or failing insulation on wire. AFCI can detect many problems, but not all.

Generally, when things get hot because of overloading, it’s at the connection point and not in the wire. For instance, a lot of electrical fires start at the plug/socket interface either because the connection is poor, there could be corrosion, etc. And sometimes they can happen when nothing is overloaded! This is one of the circumstances in which arc-fault circuit interrupters can save lives.

Overloading an electrical outlet is a common cause of electrical problems. Theoretically the breaker should protect the outlet against overloads, but it does not always do that especially if outlet or wiring is in bad condition. Do not use cords, plugs or outlets that appear damaged, replace them. Always ensure plugs are fully pushed in. Check all outlets to ensure they are cool to the touch, have protective faceplates and are in proper working order. Only grasp plugs by the plug body, keep fingers away from the front edge near the pins and do not pull plugs out by the cords.

There is a a recommendation that do not use extension cords or multi-outlet converters for appliances, because there are many problems related to US extension cords.

Damaged power cords are a serious residential electrical safety risk, and they are capable of causing both fires and electrocution. All power and extension cords should be checked regularly for signs of fraying and cracking. Power cords should not be stapled into place or run under rugs and furniture.

Besides making sure that the extension cord is in good shape, you need to be really careful that type of extension cord you use in USA. An extension cord essentially is a bundle of insulated electrical wires with a plug on each end. Electrical current flowing through wires generates heat, and when too much current flows through a wire, it can overheat and melt the plastic insulation of the wires, causing short circuits and fires.

Equipment or in-wall wire heating is normally not a problem when you plug an appliance directly into an outlet using its factory cord because the manufacturer has sized the cord appropriately for the electrical current demand of the device. The size of wiring inside wall is rated based on the breaker size on the mains panel (typically 15A or 20A). The size of the wire on the extension cord can be condiderably thinner, and the mains panel breaker might not protect it against overheating due overload. Some better extension cords can have their own overload breaker built-in but not all.

I think allowing unfused 16 gauge (16AWG = 1.5 mm2) extension cords into the market is a potentially bad link in the chain that we could probably do with cutting out. That wire is still pretty OK up to 15A load current, will get warn. If you plug it to 20A outlet and load with 20A total load, it can get dangerously hot (around 1.8 times more power heating the cable at 20A than at 15A). Pulling 20 amps through that cord made it get very hot quite quickly.

In fairness, it used to be much worse. 18 gauge (maybe even 20 gauge) extension cords were available many years ago, but regulators had the sense to make 16 the minimum as time went on.

There are also small compact ungrounded extension cords that have such designs whete users can plug in plug so wrongly that they are halfway out leaving the live parts so that the live main voltage can be present on the exposed mains plug pins.

Most electrical fires aren’t the result of a single thing; they’re a cascade of individually not-great circumstances combining to make a bad situation. In order to reduce the risk of fires, we’ve continually been making the not-great things less bad.

287 Comments

Tomi Engdahl says:

What is a Suicide Cord and Why It Could Kill You

https://www.youtube.com/watch?v=I_fxXGb8t_k

Hey gang! We’re winding down on a lot of projects here in Louisiana, tying up loose ends and fixing deadly electrical setups. Down here in the South, generators are a big deal. Whether you have a portable one, or a standby, having them properly hooked up is critical. We’re taking this afternoon to fix a bad generator setup, and hopefully throw a little knowledge out there that can save a life or two down the road. Thanks for watching, and we’ll see ya in the next one!

Interlock kits are specific to panel brands/sizes/etc. Do your homework and get the correct one. Couple of great websites: interlockkit.com and geninterlock.com

Tomi Engdahl says:

Beware Of These Wiring Mistakes Made On Newly Built Home

https://www.youtube.com/watch?v=St4T-ntiRw4

I found 4 mistakes that were made on a newly built home in my area. These mistakes are not against code but are signs of shortcuts being taken on both material and labor. With a little knowledge, you can either follow best practices in your own DIY electrical projects and/or work with a licensed electrician to get things installed in a professional and high-quality manner.

I have even seen outlets with no screws at all (back stab connections only) in a residential installation. When a contractor is installing hundreds of outlets a few minutes time saved on each one can add up to a lot of money at the end of the job. However I always side wire using the screws or back wire on commercial grade receptacles with screw down clamps.

Good tips I would’ve added they exceeded the number of conductors in the work box! Also if the circuit is for Lighting such as LED ceiling cans 15 amp breakers and 14 gauge wire is more than sufficient as long as the load is calculated properly and the local code is followed

Backstab, quick wire, or speed wire (whatever you wanna call it) holes can be sometimes be reused if the wire was properly removed. The problem I have with this method besides having to pray they hold the wires is that the wires can spin and eventually come loose due to that. In fact, you don’t even need a special screwdriver to release the wires. All you gotta do is pull the wire while twisting it and it will slowly come out. Bet you can’t do that with side wiring nor back wiring.

Instead of using the term back stabbing, I like to say La-Z-Wire, QuickWire or SpeedWire to avoid confusion to back wire, since people tend to use the terms interchangeably, including myself when I first entered the trade. I do not like backstab, and have seen them fail.

The worst failure of a back stab, was in a home built in the late 70s where the neutral failed on a multiwire branch circuit in a living room. The receptacles were alternating between the red and black along the wall sharing a common neutral, fed with 14/3w/G NM. A television and cable box went up in smoke, when the neutral opened when an electric fireplace was in use in a different receptacle, placing everything downstream in series with 240 volts. One good reason the code requires pigtailing the neutral when a multiwire circuit is used.

The Wago Lever Nuts that you use are so much better than the standard Wago Push-In Wire Connectors. Keep up the great work Scott!

“It was built by a reputable builder.”

But a builder does not wire a house, a builder hires subcontractors who hire supers who hire installers and expand or replace them as needed. Who’s guaranteeing that?

But there are good code inspectors, and slack code inspectors.

My main concern with Wagos is the wires use an internal busbar compared to touching directly. However, you are extremely competent doing a lot of work with them. This video has convinced me to give them a try.

So you have multiple problems here. First is the 12 awg assertion. In principle I agree however all things are never equal in the real world. A general purpose branch circuit likely to exceed the 15A/12A available with multiple receptacles should simply not be wired as such, which is why MWBC are how things are done commercially.

Sizing up is an absurd proposition when alternatives are considered, like a single phase multi wire branch circuit. It would cost no more to go 14/3 than 12/2, although you should have a 2-pole GFCI breaker which is still a savings although one that can be hard to appreciate. This gives you 30A/24A instead of 20A/16A and opens up L-L as an option if you go for the 2p GFCI. You would be surprised how many household loads tolerate 240V. Either 12/2 or 14/3 would require a larger box anyway.

The second issue is also the 12 awg assertion, but on different grounds – pun not intended. This looks like an 18 cuin box. Your pigtails don’t count either way, however if this was 12/2 it would exceed box fill. Frankly, you’re already over reasonable box fill for a traditional receptacle, and a larger receptacle including the commercial grade receptacle would be absurd there. Passing current through the receptacle: If it meets box fill by code and by reason and doesn’t violate other code it’s fine.

The third is friction connections, including but not limited to backstabbing. I will not say that I am a fan of backstabbing, just that backstabbing hate is nonsense. You can remove a backstabbed 14 by simply twisting while pulling just like a push-on Wago – more on that in a bit. Frankly I’m not a fan of hook and screw either, as far as I’m concerned everything should either have a bus bar, blade terminals that receive the receptacle itself with screw terminals for the conductors going to those blade sockets, or spliced and soldered conductors, but that’s just not the world we live in.

Wagos: Consider compact push-type. They’re smaller, easier to install, have less resistance, and most importantly are not inherently likely to become inadvertently unfastened. With the usual Wago 221 it does happen sometimes on installation, can definitely happen later, and because of that you need to check with a flashlight every time before you close up the box. I also prefer to put the line in the middle of the two loads on Wagos to minimize the resistance but you do you.

Turns out that sometimes DIY is safer and more responsibly done than professionals. Those are the people that give tradespeople a bad rap.

Professional does not always imply that the person is properly trained or competent, it just means he is getting paid regularly for a daily job. Most of the professionals I’ve seen around here are nothing short of hacks…

Tomi Engdahl says:

6 MISTAKES DIYers Make When Wiring Outlets

https://www.youtube.com/watch?v=XmiG4KzZ4sg

Tomi Engdahl says:

Why don’t Americans use electric kettles?

https://www.youtube.com/watch?v=_yMMTVVJI4c

It’s not really a mystery.

Tomi Engdahl says:

Lutron’s NEW 2022 Smart Dimmers Fix ALMOST Everything!

https://www.youtube.com/watch?v=bHxIi79tRG0

Lutron just announced new smart light switches that solve a LOT of the problems with the older Caseta switches!

0:00 Intro

0:26 Physical differences

1:30 Dimming improvements

2:34 Extra features

3:33 Is it PERFECT?

5:20 Problematic name…

Tomi Engdahl says:

Making an adapter to plug a construction heater into dryer outlet

https://www.youtube.com/watch?v=5qiKFUDTQdY

I show you how I made an adapter to allow me to power 4.8KW construction heater from from the 240V dryer outlet in the laundry room. The should come in very handy if I have central heating problems again.

Tomi Engdahl says:

Installing an RV Outlet

https://www.youtube.com/watch?v=fx5k1zx6mJo

READ THIS: I did get several things wrong. I have since gone back and put in a new #6 set of wires for the 50A plug, and moved the 20A plug over to the existing #10. If you aren’t sure, hire a professional. I should have.

We have a camping trip coming up! I needed a plug for the camper at the house, plus I also needed a normal 110v outlet on that side of the house. Let’s install one!

Tomi Engdahl says:

How to Wire a 30 Amp 125 Volt RV Receptacle

https://www.youtube.com/watch?v=ML3KDky0XLI

In this video I guide you through the installation of a dedicated, 30A, 125V R.V. receptacle to enable the connection of your RV without having to adapt down to a 15A 125V standard duplex outlet that you may have on the outside of the house. This installation is a bit unique in that I have used the appropriate cable to allow an upgrade to a 50A, 125/250V connection for a service to a Class A Motorcoach, or a larger 5th wheel style unit in the future, should the need arise.

Tomi Engdahl says:

Quick and Easy DIY 240V Outlet Install | 50 Amp NEMA 14-50

https://www.youtube.com/watch?v=F3yGUZv36gs

With the adoption of electric cars on the rise having a 50 Amp 240 Volt outlet in your garage is becoming more and more common. This type of project does not need to cost $1000 and if you have the know how you can even get it installed for under $100.

Tomi Engdahl says:

Check Your Tesla Plug

Why you MUST get an Industrial Grade Outlet

Tesla Recommended Receptacle

https://www.youtube.com/watch?v=HzcBZUPZXqA

In this quick video I want to emphasize the importance of using the correct nema 14-50 receptacle to charge your tesla at home. Ever since I moved to savannah and bought a home with a garage, I’ve been charging my tesla with a 10 dollar 14-50 outlet I had installed.

Tomi Engdahl says:

NEMA 14-50 vs 6-50: DON’T INSTALL EITHER BEFORE WATCHING THIS

https://www.youtube.com/watch?v=XNOnVxI0tvk

In this video, Chris shows the pros and cons of installing a NEMA 14-50 vs. a NEMA 6-50 receptacle for EV charging. For Level 2 EV charging, there is no functional difference between them because they are both 240-volt, 50-amp outlets. But the cost difference might surprise you.

Tomi Engdahl says:

How-To 220v/240v 4 Prong to a 3 Prong Outlet for a Welder & Test Voltages w/Multimeter! 4K HD

https://www.youtube.com/watch?v=1PANFpoUy2w

Stuck with a 4 prong #dryer style 220v/#240v outlet and want to swap in a more useful 3 prong outlet to plug in your #welder, air compressor, or other tools? This video walks you though the process safely in addition to showing how to test the voltages with a digital multimeter!

Quick walkthrough video of the following:

* How-to setup and use a digital multimeter and use it to test your 220v/240v 4 prong outlet voltages.

* How-to cut power to the outlet at the exterior/outdoor circuit breaker.

* How-to verify outlet is no longer powered.

* How-to replace the 4 prong 220v/240v 30 amp outlet (for a dryer/etc) with a 3 prong 220v/240v 50 amp outlet (for a welder, air compressor, etc).

* How-to restore power to the outlet at the exterior/outdoor circuit breaker.

* How-to test your new 220v/240v 3 prong outlet voltages.

* Verify welder works as expected plugged into the newly installed 3 prong outlet.

Tomi Engdahl says:

Welder 220V Extension Cord DIY TAKE 2

https://www.youtube.com/watch?v=3Zlh8hXe83s

Extension cord for the welder and Cut Shifty….. well, I have other ideas. Check it. Next episode is already in the works, so hopefully out in a week or so from this posting. It clears up the “cliffhanger” in this episode…

Tomi Engdahl says:

So my 240v 50amp NEMA 6-50 receptacle for my welder and kiln has to be GFCI protected?

https://www.youtube.com/watch?v=dw62MD1FRzA

FINALLY! IT’S EASY! How to wire a 220 volt outlet for a welder.

https://www.youtube.com/watch?v=3U_RRhEautM

Tomi Engdahl says:

1,200 Amps To Just One Address

https://www.youtube.com/watch?v=I6yfvCzsrAc

Electric Pro Academy – Real skills to make real money.

Synopsis:

We already tied the 600-amp pool house disconnects in, but now it’s time to finish off the other structures and energize this residential power behemoth. We’ve got some EV charging to account for, some massive new service conductors, and a bonus surprise underground! With so much to cover, this video will be less instructive than many of our other videos, but goes to show what materials, coordinations, and efforts are required to finish out such a large project.

Outline:

0:00 – Introduction & Project Recap

1:57 – Personal Transformer

5:46 – Separate Garage Meter For EV Charging

6:41 – Pool House Disconnect Touch-Up

7:20 – Installing Garage Disconnect

16:59 – Energizing The Whole System & Linemen Test

18:48 – Landing The New Service In The Main Panels

22:30 – Trenching Surprise

30:28 – Cost

Tomi Engdahl says:

Episode 16 – Service Entrance Wiring

https://www.youtube.com/watch?v=QCH8hP4h9k0

In this episode, I go over the process of wiring up a 320 amp meter to feed a shop and detached house.

Tomi Engdahl says:

Electrical FAIL: How To Fix Double Tapped/Wired Circuit Breaker

https://www.youtube.com/watch?v=PqXOoeUf6t8

In this video we show you some common safety violations to look for in your main electrical panel with a common failure being a double tapped electrical circuit breaker in your panel. A double tapped breaker means that you have 2 wires that are screwed in at the same point on the breaker. Most breakers are not designed to allow 2 wires to be pinched together under the terminal screw. But some Square D brand breakers are designed to allow double tapping electrical wiring in your electrical panel. This video shows you the steps we went through to remove the double tapped wires from the main panel.

Often times failures like these are found when someone knowledgeable with electrical wiring does an inspection for buyers under contract to purchase a house. The inspector spots the double tapped circuit breaker often in the main breaker panel, and calls it out in the report. Now you have to fix this double tapped circuit breaker or the buyer’s could bail on you, not wanting to inherit your shoddy electrical fails.

How To Fix Double Tapped circuit breakers

This is not the time to learn about double tapped wires and double tapping breakers. You need to find that double tapped main breaker before the buyer’s home inspector does, and fix it. In this video we saw the double tapped lugs inside the main breaker panel. Modifying house wiring should be done only by licensed electricians or other qualified people with experience, and knowledge of the National Electric Code.

Tomi Engdahl says:

Do you see whats WRONG here? #shorts #electrician #viral

https://youtube.com/shorts/7fL509M1HdU?feature=share

Tomi Engdahl says:

The CPSC Says Plug To Socket, Not Plug To Plug, Please

https://hackaday.com/2022/09/17/the-cpsc-says-plug-to-socket-not-plug-to-plug-please/

When the power goes out, it goes without saying that all the lights and sockets in a house stop working. Savvy rural homeowners stock up with candles, batteries, LED lights, and inverters. More foolhardy folks simply hook up their home electrical system to a generator using a mains lead with a plug on one end between the generator and a wall socket. This should be so obviously dangerous as to be unnecessary, but it’s become widespread enough that the US Consumer Product Safety Commission has issued a warning about the practice. In particular, they’re concerned that there’s not even a need to wire up a lead, as they’re readily available on Amazon.

The dangers they cite include electrocution, fire hazard from circumventing the house electrical protection measures, and even carbon monoxide poisoning because the leads are so short that the generator has to be next to the socket.

CPSC Warns Consumers to Immediately Stop Using Male-to-Male Extension Cords Sold on Amazon.com Due to Electrocution, Fire, and Carbon Monoxide Poisoning Hazards

https://www.cpsc.gov/Newsroom/News-Releases/2022/CPSC-Warns-Consumers-to-Immediately-Stop-Using-Male-to-Male-Extension-Cords-Sold-on-Amazon-com-Due-to-Electrocution-Fire-and-Carbon-Monoxide-Poisoning-Hazards

Washington, D.C. — The U.S. Consumer Product Safety Commission (CPSC) is warning consumers to immediately stop using and discard male-to-male extension cords sold on Amazon.com due to shock, electrocution, fire, and carbon monoxide poisoning hazards.

The extension cords have two male ends (a three-prong plug) and are generally used to “back-feed” electricity to a residence during a power outage by connecting a generator to an outlet in the home. When plugged into a generator or outlet, the opposite end has live electricity posing a risk of serious shock or electrocution. Additionally, the flow of electric power in the direction reverse to that of the typical flow of power circumvents safety features of the home’s electrical system and can result in a fire. The short length of some of these cords also encourages use of a generator near the home, which could create a risk of carbon monoxide poisoning. Furthermore, these cords do not comply with applicable national safety codes, such as National Fire Protection Association 70 (NFPA 70).

These extension cords were sold in multiple colors and lengths and under various brand names.

Tomi Engdahl says:

https://www.altechcorp.com/MachineDesign/Altech-Personif/Altech-E-Stops.pdf

Q: What is an e-stop and how is

it used?

A: E-stops, or emergency stop

switches, are used to ensure machine

as well as personnel safety. They are

used to provide a consistent and

predictable failsafe response on a wide

range of electrical machinery and must

stop the machine without creating

additional hazards. The devices can be

highly specialized for emergency

shutdown of equipment and meet

workplace and machine safety

standards established by international

and U.S. regulatory commissions.

Q: Is there a difference between

e-stops and regular stop switches?

A: E-stops provide what can be

considered foolproof equipment

shutdown, and always require a human

action for resetting. Often, the

switch requires an additional step—a

twist, pull, or key—in order to release

the electrical contacts prior to the

machine being in a position to be

restarted. As a general standard,

e-stops must be a red operator with a

yellow background.

These non-red operators do not qualify

as “Emergency Stops,” but can be

applied in a similar way to stop

applications. Black operators are used

as a Machine Stop, similar in function

to e-stops, but are simply a different

color. Typical application for these

devices is when the machine’s “OFF”

button is required to be manually reset

before restarting the machine. Blue

operators are an accepted designated

color for stopping water or sprinkler

systems, and yellow operators are an

accepted designated color for

shutting off gas lines. Different color

operators were designed for customers

with specific needs

Q: What standards must e-stops

adhere to in order to be consid

ered properly certified?

A: Always check with your supplier

to assure their devices are tested and

approved by appropriate institutions

relevant to your application. Some

important standards include:

IEC60947-5-1 and EN60947-5-5;

VDE0660; UL508; CSA: C22.2 No.

14-95; and NEMA Type 4X, 12. These

are some of the most used in the U.S.

while other compliance and rating

bodies also exist for other countries as

well.

Q: What types of applications are

required to have e-stops installed?

A: All industry segments mandate

e-stops for safe operation, including,

but not limited to industries involving

vehicles and transportation, medical

treatment and diagnostics, industrial

machinery, oil and gas, food and

beverage, water and waste water,

and instrumentation. Therefore,

designers will want to have a knowl-

edge of e-stop fundamentals, and

switch characteristics and capabilities,

as well as the international and U.S.

standards and compliance require-

ments that need to be met for their

application.

Q: How can I begin to select the

right e-stop for my application?

A: The first step is to determine

where the e-stop fits within your

machine control system and what

category of emergency shutdown is

needed according to the standard you

are adhering to.

Tomi Engdahl says:

For high power connections (usually three phase) you want to look for Series 16 CAMLOCK connectors. That is the closest thing to a standard for high current.

Tomi Engdahl says:

PowerLock is a nightmare if you have a field failure. Most mid sized events dont carry a whole set of spares, with CAMs you can carry one spare cable and use it to get thru the gig, with PowerLock, although superior, its too much hassle to catch on. The safety issue is dealt with by the US only requiring “qualified personnel” use CAMs to ensure the correct mating order.

Tomi Engdahl says:

You can trade any failed cam for any other, even if its marked the wrong color. The point of Power lock is that its impossible to plug each wire anywhere other than the correct socket. So to have a backup, youd need to carry 5 extra cables instead of 1.

Tomi Engdahl says:

Besides, many of us reverse gender the Neutral and EGC so its not really a functional concern with CAMs either

Tomi Engdahl says:

Pin and sleeve connectors are pretty common at high end facilities for 100A and 200A setups. But they’re super expensive so many just skip them and go straight to CAMs

https://www.platt.com/s/200-amp-pin-and-sleeve-connectors?cat=4virft8w

Above that its all CAMs

Below 100A the most common options are the L14 series, L21 series, or CS6364/5

Tomi Engdahl says:

the wire gauge historically came from the number of dies the wire was drawn through, starting with 1 being the raw bar. The sizes progress downwards as the number increases. The dies were the thing that was standardised and the produced wires had some variation based on material.

Gauge is the size/number of dies a wire is drawn through to reach a particular size. Standard in that everyone starts out with the same size dies. Higher number = tinier the wire. It allows for normal manufacturing variances in soft(ish) metals. https://www.powerstream.com/Wire_Size.htm

“Each AWG step is the 39th root of 92, or approximately 1.12293 times the change in diameter.

0000 AWG is defined as 0.46 inches in diameter, and 36 AWG is defined as 0.005 inches in diameter. All other sizes are derived as logarithmic steps between these two defined sizes. There are 39 gauge steps between these sizes, and the ratio is 1-to-92 in diameter.”

This quaint system dates to 1857 and has origins in the original manufacturing process, where a large rod is successively drawn through a series of smaller and smaller dies until the desired diameter is achieved.

(Ref. https://www.techtarget.com/searchnetworking/definition/American-Wire-Gauge )

Tomi Engdahl says:

Above 125Amp se usually use what se call Power Locks that Will work with Higher Amperage. Cheers

Tomi Engdahl says:

Camlocks are the most common for >50A.

California style plugs (50A) are getting more common in the food truck industry

I will also add that NEMA L21-30 is very common for 30A 120/208 3ph

You will find:

277/480 3Phase

120/208 3Phase

120/240 single phase

If you are using 480 for entertainment, it is for HVAC gear, big motors or just distribution to portable transformers that will get you to 120/208(or whatever you require).

Most of the gear will be 120/208v using either 1 or 2 legs of the three.

Motors will use all three.

Primarily you pull from the house in camloc (100-400amps)to your own gear. You use whatever connectors you like, there are hundreds of different applications.

Indoors you will find every flavor of twist lock.

Outdoors you will find a world of creativity.

There is very little RCD/GFI protection, be careful.

I believe the USA also has cee plugs, but yellow (110V), until, like, 32A monophase? (The internal pin layout is turned like 30degrees compared to EU)

Tomi Engdahl says:

For three-phase power, over 60A, we typically use cam lock. Under 60A, you can see Y560 Woodhead.

For smaller events some use a Range plug… 240 v and 40 amps (as high as 70 amps…)

For less than 30A, we see a lot a L21-30.

50 amps Single Phase I use a Nema 14-50 or a CS conector like a Marinco CS6364N

anything larger or 3 phase use cam.

Tomi Engdahl says:

the iec309 connectors are nice, especially the mennekes

usa uses camlocks, and NEMA twist locks.

cal 50 are non-nema, but are a standard all their own.

then theres stage pin and all kinds of other stuff

Tomi Engdahl says:

90% Of Homeowners Have Never Seen This Dangerous Electrical Device

https://www.youtube.com/watch?v=PiueoEw2x40

Self-Contained Devices or SCD are common in mobile homes and RV’s but have a very unique wiring method that is not proven to be robust over time. If you have these devices in your home you do have options and better understanding what you are up against is a good first step.

Viewer comments:

I was an RV tech for many years and these were so problematic because of the weak connection. Look up the wiring for the 3 way switch, it was a nightmare. They should be pulled from the market but the RV industry gets away with a lot of things like this.

Yup, RV industry gets away with all kids of crap because they are trying to reduce the weight of the rig, and also keep costs down. No metal boxes and less wiring runs means less weight. Less weight means better fuel economy for the tow vehicle, and that means less emissions. They all figure thats a win win for the environment. Problem is that lots of these plastic pieces of junk get pulled out and thrown in the dump where it takes 10 million years to break down the plastic.

yeah, I mean: Screws can loosen during earth quakes – on an unrelated note: Of those few times of service each year, an RV spends time on and off roads, shaking those presfits loose. Now, luckily only domestically rated equipment contains notes about retightening screws after moving equipment.

Beautiful design that shows the manufacturer has taken the time to understand how to convey current safely through a UL listed outlet. The pass through, unbroken wire transfers the full rated current, but eliminates the need for the failure point of a screw terminal, the wasted time stripping and dependence on the skill of the “World of Idiot” electricians out there. Hats Off to the company and hope all residential boxes duplicate and adopt this in the future…

Back when I worked as a service tech for a local electrical company, we came across these in a double wide. In this case, it was switches we had to deal with. We literally replaced them with a cut in box and traditional switch.

A friend’s mobile home had numerous failures of this kind of receptacle. We had to rewire each of them. It was a real pain.

Tomi Engdahl says:

Avoid These 5 DIY Electrical Mistakes

https://www.youtube.com/watch?v=U4UMuQ7t0Vw

I have made plenty of mistakes over the years and some of them on past videos where viewers were nice enough to point out my errors. I will run you through 5 mistakes I have made in hopes that you can avoid these same issues on you DIY electrical projects around the house.

25 Most Common DIY Mistakes When Wiring Outlets / Receptacles

https://www.youtube.com/watch?v=qT-iwVp9Anc

25 Most Common DIY Mistakes Installing Outlets – What to do and what not to do when you install or replace a new or existing electrical outlet/receptacle.

Tomi Engdahl says:

Yeah, there is no 110/220v in the US. Those are misnomers. Single phase household voltage is 120/240. For entertainment we use 120/208, from a three phase wye transformer.

110/220 was the last remnant of the battle for the voltage standard. Eastern Colorado and some of the states east and NE from there used the 110 standard. Appliance manufacturers had to ship two separate skus and they were the biggest complainer about the standard problem. I’m pulling this from memory but I want to say the standard finally switched in the 110 areas to 120(like the rest of the country) sometime in the 70s. My guess is people still say 110/220 because it just feels better to say without knowing any better.

it’s a common misconception so no worries. The standard requirement for most utility companies is to deliver 120vac +/-7%. If you are experiencing this you can give them a call and they are required to make the necessary adjustments in that area’s regulators to suit all the services from front to back. Fyi, if you are ever having low voltage issue.

Tomi Engdahl says:

Gauge is the size/number of dies a wire is drawn through to reach a particular size. Standard in that everyone starts out with the same size dies. Higher number = tinier the wire. It allows for normal manufacturing variances in soft(ish) metals. https://www.powerstream.com/Wire_Size.htm

Tomi Engdahl says:

25 Most Common DIY Mistakes When Wiring Outlets / Receptacles

https://www.youtube.com/watch?v=qT-iwVp9Anc

25 Most Common DIY Mistakes Installing Outlets – What to do and what not to do when you install or replace a new or existing electrical outlet/receptacle.

Tomi Engdahl says:

Which Splicing Device is Best? Push Ins Vs. Wago Vs. Wirenuts

https://www.youtube.com/watch?v=gC3PI2Plw98

Tomi Engdahl says:

US mains power on normal outlets is 120V. The voltage between two live wires can be 240V (normal home split phase power) or 208V (power from three phase feed in larger buildings).

Tomi Engdahl says:

The simple resettable fuse/breaker on the extension cord will protect the extension cord against overloading, mainly the usually quite thin copper cable and in some cases less than perfect cheap outlets. The contacts of the outlets have their designed current-carrying capacity. If it handles more current than its rated FLC, the excess current causes heating in proportional to the square of the current. The contact between outlets and plug must be as tight as possible. The minimum is the contact resistance, the minimum is the heating. The contact resistance increases when there is looseness in the connection. The reduction of the area increases the resistance. Further, the increased resistance leads to more (I2R ) heat losses. This heating further increases the heating problem. And, finally electrical outlets damage.

If the outlets on extension cord would be good quality and wire would be thick enough, there would not be need for fuses on the extension cord and there would be less electrical fires (the European way).

Tomi Engdahl says:

Adding surge protection does not help in any way to avoid those bad contact on extension cord type fires unless the surge protector extension manufacturer has used better contacts on oulet that cheap Chinese extension cord. Extension cord fires happen very often due to improper use, bad condition of the cord (old cord with loose contacts on outlet) and overloading.

A surge protector blocks or diffuses voltage spikes or surges that can damage electrical equipment. As such surge protector does absolute nothing to avoid those loose contacts and high power load cord meltdowns. Surge protectors can also become a fire hazard themselves.

Tomi Engdahl says:

http://www.zohnson.com/news_info/Fooled-By-A-Fake-UL-Certificate-n72011.html

Tomi Engdahl says:

Most power strips just aren’t built for continuous use at full load in the confined spaces behind sofas and such they end up in. They just aren’t. You can certainly buy ones that are up to the task, but you’ll be paying more for one strip than you did for the space heater.

So you have a choice to make: Try to educate folks on the dozens of variables at play so they can do a complete analysis on a case by case basis with their specific combination of components. …Knowing full well that even “smart” people given all this information will still screw the calculation up more often than not.

Or, or you can simply advise folks to simply not use power strips with space heaters.

So in conclusion: Smart people don’t use power strips with space heaters. If you’re a smart person and you disagree, re-read the last sentence until you either agree or you stop kidding yourself into believing you’re actually smart.

Tomi Engdahl says:

Yes, this is because the regulations in the USA do not require extension cords to have a current capacity the same or better than what the wall socket wiring does. You can easily have a 16 amp socket and plug a 10 amp rated extension cord into, and then plug in a 16 amp heater into the extension cord. Plus other devices at the same time, too.

Always, always make sure your extension cords are rated at the same or better than the wall socket & breaker’s capacity, and never exceed the wall socket’s and circuit breaker’s total capacity.

Improving our electrical regulation on product manufacturing could improve this situation, but until then, people will have to math better.

Tomi Engdahl says:

There is a thermal component inside breakers on extension cords. When it gets hot enough, the bi-metal strip bending causes tripping. There is a wire near that bimetallic strip that passes the load current, when current grows high enough the strip gets hot enough to cause tripping. Anything they would get the breaker hot enough will trip it. A severe hot meltdown situation on the other end if the extension cord case just don’t heat up that the breaker enough to trip.

To protect against such situation the heat reacting component should be put very near to the location where the heat is generated. I quess to be for sure effective there would need to be a thermal fuse built into every current carrying contact (meaning at least six thermal fuses for three outlet extension cord). Or maybe one thermal fuse per outlet could work.

Tomi Engdahl says:

https://www.electricalvolt.com/2022/01/how-to-prevent-electrical-outlets-from-overheating/

Tomi Engdahl says:

Upgrading My Own House to 1,000 Amps

https://www.youtube.com/watch?v=6KtcOqOfvXc

Synopsis:

Joel doesn’t buy suits and ties, gizmos and gadgets, or toys and trinkets; he just wants power. Electrical power, that is. With 8 kids approaching (electric) driving age, big cooking and cleaning appliances, a pool out back, and a carriage house over the garage, there is a big need for big power.

While 1,000 amps should reliably get the job done for many years to come, there is a smarter (and cheaper) solution. Generally home electrical services are calculated according to the maximum draw, but if the panel could keep track of which loads were on and off, less power would be required. SPAN is our current preferred smart electrical panel for this very reason. Follow our channel for more installations and demonstrations of how SPAN can make your house genius.

Laced within the technical instruction are recommendations and points of professionalism employed daily by Jefferson Electric masters, journeymen, & apprentices.

Tomi Engdahl says:

Split phase 120V/240V is NOT 180 degrees out of phase

https://www.youtube.com/watch?v=uRKbX74lBgU

120/240 and 120/208 Volt Transformer Secondaries

https://www.youtube.com/watch?v=xMZkKI5rleg

Tomi Engdahl says:

Delta and Wye – Volts, Amps, & VA

https://www.youtube.com/watch?v=dLqz_zPpgHI

Explanation of Voltage, Current, and Power Relationships in Delta and Wye Transformer Configurations.

Tomi Engdahl says:

Isolation Transformers can save your life, and your equipment.

https://www.youtube.com/watch?v=3rvEdHyAd2k

Isolation transformer explained and demonstration

https://www.youtube.com/watch?v=nMHp_DFSeg0&t=512s

Tomi Engdahl says:

The BIGGEST Mistakes DIYers Don’t Know They Are Making When Wiring Receptacles | How To

https://m.youtube.com/watch?v=RO6Kq65HwNw

Tomi Engdahl says:

The BIGGEST Mistakes DIYers Don’t Know They Are Making When Installing Metal Electrical Boxes

https://www.youtube.com/watch?v=LrZEz7SOwW0

In this video I show you some of the biggest mistakes made when installing metal electrical boxes. They can be incredibly dangerous if some steps are overlooked or forgotten!